Taking into account instructions on labor protection by the employer

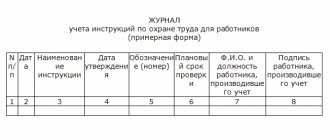

A log of labor safety instructions is kept.

The manager, along with the development of regulatory documentation on labor protection, is obliged to organize a record of instructions. This requirement is met for convenience when performing work, that is, to ensure control over the availability of documents and set deadlines for their processing.

To do this, a logbook is filled out, the approximate form of which is indicated in the methodological recommendations of the resolution of the Ministry of Labor. It is proposed to place the following information in the columns:

- When the document is handed over;

- Title of the document;

- Serial number or designation;

- Number of copies issued;

- Recipient's last name and initials;

- Signature of the person receiving the document.

Any organization must monitor the availability of labor protection instructions and the date of their revision.

As a rule, this function is performed by an occupational safety and health specialist.

If something has changed

Sometimes the situation looks different. For example, over a five-year period, have people’s working conditions changed, or have higher standards been revised? How long will the labor safety instructions be valid now?

In such a situation, any instructions regarding production safety and labor protection must be reviewed by the head of the organization ahead of schedule. If necessary, new ones should be promptly drawn up and approved.

Does the validity period of labor safety instructions for workers change in cases where more modern equipment has been introduced and technological processes have been changed? This situation relates to those mentioned above, that is, we are talking about a change in working conditions. Accordingly, instructions must be reviewed and replaced in a timely manner.

If an accident occurs (an industrial accident), it is investigated. Having analyzed the results, as well as the statistics of occupational diseases, the management of the enterprise is obliged to draw appropriate conclusions and adjust the existing instructions.

Frequency of revision of labor protection instructions

Employers often underestimate the importance of developing these documents. Often this is entrusted to an occupational safety specialist, and department heads simply sign. If an accident occurs to an employee, the inspector will check how he was instructed in occupational safety when performing a specific type of work. If the instructions do not set out the rules for their safe implementation or provide references to outdated safety standards, the inspector will consider the employee’s training to be formal. This will seriously worsen the employer's position. Therefore, it is worth paying attention to both the development of IOT and its periodic checking for relevance.

Download documents from the article

Order on the appointment of persons responsible for the development and revision of IOT

In general, the period for reviewing labor safety instructions is at least once every 5 years. For electric power enterprises, the standard period is once every 3 years, which can be explained by the increased risk of electric shock to workers.

Validity period of labor safety instructions

IOT is valid as long as there is a need for it. This means that the life cycle is not limited to any specific period of time. There are no mandatory requirements establishing a planned inspection period. This means you can do this more often, but you cannot do it less than once every five years.

SAFETY 360° Automated workplace will help organize labor protection

- Information support, updating and data analysis

- Optimization of document flow on labor protection

- Organization of briefings, medical examinations and training

- Drawing up standards for issuing personal protective equipment

Try for free

If, for example, there are instructions for working with a hammer, the requirements for the worker may be revised, although the process of working with this hand tool remains the same. The qualification requirements for the employee must be specified, so when changes in legislation occur, appropriate amendments must be made. Let’s say that from July 1, 2031, only people under 50 years of age will be able to work with a hammer. If the Rules come into force this year, then the employer is obliged no later than July 1 to familiarize the employee with these changes by conducting an unscheduled briefing on the already updated IOT. If the employee is introduced to the new rules not on July 1, but, say, on July 12, and during this period of time an accident occurs with an employee over 50 years old, the employer will bear administrative liability under Part 1 of Article of the Code of Administrative Offenses of the Russian Federation.

Occupational safety instructions: 7 important questions

Every third employer entrusts the development of instructions to an occupational safety specialist. But should he do this kind of work? Read in the magazine “Handbook of Occupational Safety and Health Specialist” how the development process should be organized and how to resolve conflicts of interest with heads of structural divisions. Read the magazine article

Early revision of labor safety instructions

According to the Methodological Recommendations of the Ministry of Labor from the year, the employer is obliged to revise the IOT ahead of schedule if there are changes in the labor protection rules and in the standard IOT taken as the basis for local ones. Also, paragraph 7 of the Methodological Recommendations states that if the working conditions of workers change, the instructions should also be reissued. This will be required when introducing new equipment or technology, or dismantling old equipment. The new IOT must be issued to the employee for study before he starts working on the new equipment.

In addition, the GIT inspector may order a review after an accident. The employer has the right to make such a decision independently, after analyzing the investigation materials, if it turns out that the material in the IOT was presented formally and does not have a significant impact on ensuring the safety of workers.

Download from the Occupational Safety and Health System

- Ready-made IOT sample

Is it necessary to review the instructions?

IOT is a regulatory act that specifies labor safety requirements when working in a production facility, on the territory of an institution, on a construction site, and in other places where official duties are performed.

A few words about the documents that are required to be drawn up in every company

The form includes the following sections:

- general safety requirements;

- safety requirements that an employee must comply with before starting work;

- safety requirements that an employee must comply with while working in production;

- safety requirements to be fulfilled by the employee in the event of an emergency;

- safety requirements fulfilled by the employee who has completed his work.

What is included in the finished form

Additional sections may be added to the form. According to the law, safety rules are:

- typical;

- special. Such codes are created specifically for employees of specific departments.

And if the enterprise is new, the businessman has the right to introduce temporary instructions.

Safety rules are divided by position, individual professions, and individual types of work.

Who needs a vault

So a set of safety rules is developed for:

- managers;

- electric welders;

- machine operators;

- locksmiths;

- electricians;

- cleaners;

- laboratory technicians;

- milkmaid

It is necessary to develop safety rules for the company. The paper is developed by management itself. The registration procedure is described in legislative acts. The finished document must be reviewed by a lawyer. It is signed by interested parties and the employer.

If the requirements specified in the IOT have changed, the form must be updated. And after such a set of safety rules has been implemented in the company, such paper must be in the institution. Moreover, all employees of the company should know about the location of this form. It’s best to place this set of rules on an OT stand.

Note! The owner of the company can distribute copies of the set of rules to his employees. These actions are recorded in the instructions log.

The finished form must be revised. And this rule does not change whether changes were made to the requirements included in it or not.

What labor safety instructions should be developed for the employee?

The development of this form and the set of rules described in it is carried out by the owner of the company. And the person responsible for OT checks and approves it. How often labor safety instructions for workers should be reviewed is also decided by the occupational safety specialist.

Important document for a specialist

The occupational safety worker is also required to keep a log of instructions. The following data is entered into it. This:

- date of issue of paper;

- Name;

- serial number of the document, its designation;

- the number of copies that were handed out;

- Full name of the person who received this document;

- signature of the person who received this paper in hand.

The maximum validity period of an IOT is 5 years. And if work at a given enterprise is dangerous, then the approved form undergoes a scheduled inspection after 3 years. But this schedule does not always need to be followed.

Important! There are times when a manager needs to revise a set of rules ahead of schedule.

The owner of the enterprise has the right to review the finished IOT ahead of schedule.

Instructions on labor protection by profession and type of work

It is necessary to review the set of safety rules when:

- labor safety rules, GOSTs or other regulatory and legislative documents have been amended. Therefore, the owner needs to periodically review the code of laws and carefully monitor all changes;

- working conditions at the enterprise have changed. For example, there are more harmful substances that will negatively affect the human body. Such changes are usually detected after laboratory tests are carried out in the company. If the amount of harmful substances has really increased, then employees of the enterprise are recommended to use additional protective equipment;

- New equipment was put into operation at the enterprise or old electrical installations were removed. In this case, the boss must instruct his employees about innovations and the possibility of using additional protective equipment. The businessman is also obliged to instruct employees on what they need to do in difficult situations;

- a tragedy occurred at the enterprise. The completed form is also reviewed if one of the company’s employees has been diagnosed with an occupational disease. Moreover, the businessman must conduct an investigation, establish a connection between the requirements set out in the IOT and the likelihood of the employee developing an occupational disease;

- this is required by an occupational safety specialist or other inspector who comes to the company.

Important! The inspector has the right to force the head of the company to change the IOT. And after some time, the IOT employee has the right to check how the head of the company fulfilled this requirement.

What is the order and what does it include?

An order to approve changes is issued before they come into force. The company employee must be aware of the changed security requirements in advance. Local acts are changed at the time of their adoption. Therefore, if the IOT was approved by order, then changes to the finished form or cancellation of the form must also be made by order.

As mentioned above, IOT is valid for 5 years. At hazardous enterprises, paper remains for 3 years. This period also applies to papers developed for enterprises working with the electric power industry.

If no changes have been made to the template established by law in the laws, requirements or other documents on which the paper was drawn up, then the head of the enterprise can extend the validity period of his already completed IOT. He needs to issue an order that the validity period of the IOT is postponed. The Order must indicate the new validity period.

Important! An employer can extend a completed set of rules for 5 years. Moreover, a businessman can do this only 2 times.

The law does not describe how the manager conducts a review and changes the executed paper.

We invite you to familiarize yourself with Mortgage Interest Compensation

How the old form is revised. And what does the new instruction look like?

But this is roughly how it is done.

Head of the organization:

- Together with the head of the structural unit, he studies the regulatory framework, revises the finished document, and develops a new document. The manager can also involve other officials in the development of the document. For example, he can involve employees of SES, Rostechnadzor, and Gospozharnadzor in this process.

- Together with a HR department specialist, he develops an order to amend the current set of rules.

- Signs the order and papers.

The order shall indicate the name of the amended instruction.

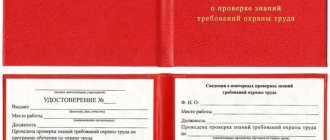

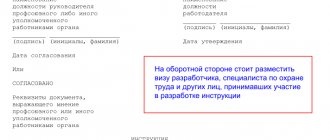

All interested employees must familiarize themselves with the new document. The back side of the new document must bear the signature of the developer and the head of the department.

The first page of the instructions should also contain the following important information. This:

- the date when changes were made to the form;

- a stamp confirming that the employer has revised this document;

- signature, position and transcript of the person who is responsible for the relevance and legality of this paper and ensures safety at work;

- validity period of the new document.

Important! After introducing a new instruction, the manager familiarizes employees with the new document.

Moreover, the leader must:

- briefing;

- internship;

- knowledge test.

During training, the employee should pay attention to the following factors.

- factors that can cause significant harm to the human body and health during work;

- options for performing one’s job duties, which are described in the job description, and which reduce the risk of exposure to negative factors;

- requirements described in the acts in the IOT.

IOT must be performed by all employees working at this enterprise. Moreover, this includes employees working both on a permanent and temporary basis. Students undergoing internship at this enterprise are also required to follow a set of safety rules.

The finished document is printed in 3 copies. One of these copies is issued against receipt to the performer.

The second copy is received by the head of the structural unit. And the third copy remains with the head of the company.

All documents regarding safety rules can be handed over to an employee of the company. But they are issued only against receipt.

Important! The finished instructions should not contradict the regulatory and legislative acts in force on the territory of the Russian Federation.

If the company's name has changed, then there is no need to create a new set of safety rules. Also, there is no need to make changes to the finished form even if the company’s occupational safety officer has changed. The specialist may issue a new order stating that old documents are considered valid until new changes are made to them.

If the head of the company does not have an IOT, then during a prosecutor’s inspection a severe punishment may be imposed on him.

An entrepreneur may be subject to:

- disciplinary action. Its size is determined by an employee of the inspection company;

- administrative fine in the amount of 5,000 to 80,000 rubles.*

Usually, the fine is paid instead of the entrepreneur by another person responsible for this document. But if the head of the enterprise has not introduced IOT to his employees, then all responsibility from the enterprise’s employees is removed and transferred to him.

And if the head of the company has an IOT, but this paper has not been updated for a long time, then a fine will also be issued. This paper must be paid.

It is not difficult to draw up labor safety instructions. The manager just needs to study all the current legislative acts and carefully draw up the necessary paper. A businessman should not neglect this document. Without it, the head of the institution will have a lot of problems and will be tormented by various checks.

*Prices are current as of July 2020.

The employer organizes the verification and revision of labor safety instructions for employees. A revision of the instructions is due. Revision of labor safety instructions is an ambiguous event and therefore requires additional clarification. It turns out that it is not only necessary once every 5 years.

The instruction is valid for 5 years.

Validity period of labor safety instructions

Safety is a very important area for any business . The main document that controls the entire work process is the labor protection instruction. The primary purpose of the above paper is to instruct new employees in the safe performance of job duties.

The conditions contained in the instructions are mandatory , regardless of length of service and position held. If the behavior of a subordinate goes against the instructions on labor protection, then the head of the institution may resort to an extreme measure - terminate the employment contract.

Article 81 of the Labor Code of the Russian Federation states that a manager is not obliged to be responsible for the actions of an employee who, at least once, committed a gross violation of the requirements set out in the document, which caused serious consequences (accident, work-related injury, etc.).

Subordinates, whom the director of an institution has instructed to develop instructions on safe behavior in the workplace, quite often forget about one important point - the document is relevant only for a certain period of time , and then it is subject to revision. The importance of this procedure is this. The regular work of an organization depends on numerous factors: technical wear and tear of instruments and equipment, routine repairs, staffing levels, regular training, etc. All these indicators are reflected in the final result.

So, how many years has the adopted labor safety instruction been in effect? Current legislation recommends revising the document every 5 years . As practice shows, if during this time the enterprise has not undergone major changes, as well as a revision of the standard package of regulatory documents, then you can simply approve the previous instructions on labor protection.

Revision of occupational safety instructions

Employers underestimate the importance of developing occupational safety instructions. Often this is carried out by the labor protection service, and department heads simply sign them at the request of specialists.

If an accident occurs to an employee, the inspector will check how the employee was instructed on labor protection when performing a specific type of high-risk work. If the IOT does not set out the rules for safe work or makes reference to outdated safety standards, the inspector will consider the employee’s training to be formal. This will seriously worsen the employer's position. Therefore, pay close attention to both the development of the IOT and its periodic checking for relevance during the period of validity.

Here's another piece of advice for you.

Of course, this situation is not defined in any way by law. However, in our experience, this is exactly the moment when it is worth reviewing the labor protection instructions again. When you hire a new occupational safety specialist, or change outsourcing company. In these cases, it will be very useful to check the correct drafting of documents from past authors.

As a result, the review is carried out once every five years, with the exception of cases of changes in legislation, production technologies or incidents (accidents, occupational diseases or inspection requirements). The algorithm for developing and revising instructions must be reflected in the procedure of the occupational safety management system “Procedure for training workers in occupational safety”

Early revision of labor safety instructions

The guiding document is the Methodological Recommendations of the Russian Ministry of Labor for the development of IOT from year to year. They determine how often labor safety instructions are revised: the employer is obliged to do this ahead of schedule if there are changes in the rules on occupational safety and in standard IOT, taken as the basis for local ones. Also, paragraph 7 of these methodological recommendations states that if the working conditions of workers change, the instructions should also be amended.

This does not mean that if the UT class has changed from 3.2 to 3.3, it is necessary to cancel or change the current document. This means that if a worker, instead of semi-automatic welding, now works on a manual machine, then he needs to be familiarized with IOT for manual welding. When introducing new equipment and technology, the instructions must change accordingly. If the old equipment is dismantled, then it is necessary to remove the old one from use and issue a new IOT. The new one must be accepted and given to the employee for review before the employee starts working on the new equipment.

The State Traffic Safety Inspector may order a review after an accident. The employer has the right to make such a decision independently, after analyzing the investigation materials, if it turns out that the IOT material is presented formally and does not have a significant impact on ensuring the safety of workers.

In what cases is it necessary to make changes ahead of schedule?

The owner of the enterprise has the right to review the finished IOT ahead of schedule.

Instructions on labor protection by profession and type of work

It is necessary to review the set of safety rules when:

- labor safety rules, GOSTs or other regulatory and legislative documents have been amended. Therefore, the owner needs to periodically review the code of laws and carefully monitor all changes;

- working conditions at the enterprise have changed. For example, there are more harmful substances that will negatively affect the human body. Such changes are usually detected after laboratory tests are carried out in the company. If the amount of harmful substances has really increased, then employees of the enterprise are recommended to use additional protective equipment;

- New equipment was put into operation at the enterprise or old electrical installations were removed. In this case, the boss must instruct his employees about innovations and the possibility of using additional protective equipment. The businessman is also obliged to instruct employees on what they need to do in difficult situations;

- a tragedy occurred at the enterprise. The completed form is also reviewed if one of the company’s employees has been diagnosed with an occupational disease. Moreover, the businessman must conduct an investigation, establish a connection between the requirements set out in the IOT and the likelihood of the employee developing an occupational disease;

- this is required by an occupational safety specialist or other inspector who comes to the company.

Important! The inspector has the right to force the head of the company to change the IOT. And after some time, the IOT employee has the right to check how the head of the company fulfilled this requirement.

What is the order and what does it include?

Review procedure

Attention! Responsibility for compliance of local acts with legal requirements lies with the labor protection service. Responsibility for compliance of the labor protection instructions with the requirements of the operating manual lies with the developer of the instructions - a technical specialist or manager.

An order approving changes to the IOT must be drawn up before the change in legislation comes into force. The employee must be promptly informed of the changed safety requirements. Local acts are amended in the order of their adoption. If the IOT was introduced by order, then it must also be amended or canceled by order.

When changing an occupational safety specialist, is it necessary to review and re-approve the occupational safety instructions? What is the procedure for agreeing on old instructions with a new specialist? There is no need for revision in this case, but a new specialist, having found significant violations in existing instructions, must revise them. This is the decision of the specialist himself.

Is it necessary to replace the instructions on labor protection (planned revision of the instructions in 2020) when changing the name of the organization? What legal act should be followed in this situation? Despite the name change, the organization remained the same, so orders and other administrative documents can be replaced with new ones gradually - when changes need to be made to them.

The legislative procedure for making changes to local regulations in connection with changing the name of an organization is not prescribed. In this case, during the transition period, it is advisable to issue an organizational and administrative document (order) stating that, for example, labor protection instructions (list them) continue to be valid until they are revised.

Approval and storage of instructions

The instructions are coordinated with the trade union and other services (for example, with the legal department, labor protection service, heads of structural divisions, etc.). After which, labor safety instructions are approved and put into effect by order of the employer.

Note: The title page must contain the “I approve” glyph, the date and the employer’s signature. As well as notes on agreement with the primary trade union organization, and in its absence, with the labor protection commissioner.

Labor protection instructions are recorded in a special journal by an authorized employee of the labor protection service.

A control copy of the instructions is stored in the labor protection service, and the required number of copies is issued to structural units.

The fact of issuing instructions must be recorded in a special journal.

All employees instructed according to the instructions must be familiar with it and signed it.

Review procedure

Attention! Responsibility for compliance of local acts with legal requirements lies with the labor protection service. Responsibility for compliance of the labor protection instructions with the requirements of the operating manual lies with the developer of the instructions - a technical specialist or manager.

Who develops labor safety instructions

An order must be issued.

The manager is obliged to ensure the development of labor protection instructions; this is a legal requirement.

The development of instructions on health and safety is carried out by:

- One of the managers of this enterprise, and the consultation is carried out by the same OT services;

- The organization that has the right to develop this instruction.

The role of an occupational safety specialist is to provide methodological recommendations and consultations in this area.

When considering the draft instructions, it is imperative to take into account the opinion of the primary trade union organization. It is important for the employer to include in the functional responsibilities of managers the development of occupational safety instructions in order to avoid controversial issues.

Development sequence:

- An Order or other administrative document is issued, which appoints the person responsible for the development and sets the deadline for completing the work. It is imperative to designate someone to establish general control over the execution of the Order;

- In the process of performing work, a labor protection specialist provides consultations and issues methods for drawing up instructions, and also informs about new clarifications and changes in the Rules and other regulatory documents;

- After preparing the draft instructions, it should be agreed upon with the services involved in the technical process, for example, energy or mechanics, representatives of the trade union committee, an occupational safety specialist and the site manager;

- Next, the agreed project is approved by the head of the enterprise and put into effect by the Order of the same head.

Procedure for extending the validity period

The review procedure is not described by current legislation. The labor protection instruction is an internal document of the enterprise, therefore it is believed that each manager has the right to establish an individual procedure for the adoption and revision of this regulatory act.

Often it happens like this:

- Heads of structural units study the regulatory framework, and then develop and revise the document.

- The HR specialist draws up an order.

- The manager approves the above documents.

The order should reflect the names of the instructions affected by the changes.

At the same time, we must not forget that the newly-minted document must be brought to the attention of interested parties. In addition, the developers of the instructions and heads of departments must place their signatures on the reverse side of the labor protection instructions.

The first page of the extended document cannot do without the following details:

- the date fixing the deadline for making adjustments;

- a stamp reflecting the fact of the revision;

- signature, position held and transcript of the person responsible for the relevance and legality of the document ensuring safety at work;

- validity period of the updated local act.

Article 212 of the current labor legislation requires that for each citizen starting to perform duties in a new workplace, a set of introductory activities is carried out: instruction, internship and testing of knowledge related to a safe work process.

Important! An employee cannot be blamed for violating labor protection requirements if the employer did not ensure timely familiarization with them.

In Art. 225 of the Labor Code of the Russian Federation sets out the condition that instructions to ensure the safety of the work process, as well as training in first aid in the event of unforeseen circumstances, are the responsibility of the employer. Accordingly, if the director of the organization did not bother to comply with the above legal requirements, then he does not have the right to accuse his subordinates of violating the requirements of the labor protection instructions .

Scheduled reviews

The document regulating a safe environment in the workplace should be reviewed and rechecked at least once every 5 years . The immediate heads of departments are responsible for carrying out such actions.

If during the entire period of validity of the labor protection instructions not a single emergency event has occurred (injury at work, accident and occupational disease), and nothing has changed in the current regulatory framework, then the responsible officials can simply extend the validity period of the internal local act by another 5 years.

Main document

The main regulatory document of an enterprise on safety issues is called labor protection instructions. It relates to internal regulatory documentation.

The purpose of the instructions is to provide instructions on the topic of labor protection relating to each workplace. Its requirements are mandatory for all employees. Those who refuse to comply with them are considered violators of labor discipline with appropriate sanctions.

For example, Article 81 of the Code allows the employer to terminate the employment contract in the event that the employee grossly violated these requirements at least once, and this led to serious consequences (injury, accident or catastrophe) or threatened the occurrence of similar consequences. Disciplinary offenses under Art. 192 of the Labor Code are punishable by penalties, including dismissal.

Reasons for revision of instructions

The instructions are revised in certain situations.

The contents of the instructions need to be reviewed periodically. This function is assigned to department heads. But the material contained in the document may be revised before the due date:

- if changes are made to the Labor Safety Rules, GOSTs and other documents adopted at the legislative level. This work is organized at the enterprise, that is, it is necessary to periodically monitor changes in legislation;

- working conditions have changed. For example, harmful conditions affecting the body have increased.

This was shown by laboratory studies, on the basis of which the maximum permissible concentration of harmful substances on the body has increased. In this case, it became necessary to use additional personal protective equipment;

- the introduction of new technologies and the replacement of outdated equipment with new ones is also the basis for amending the HSE instructions.

The technology has changed, based on this, it is necessary to instruct people involved in the technical process on new work methods, including what PPE to use, and what to do if unforeseen circumstances arise;

- revision of the instructions is required if an accident, incident or other incident occurs, as well as based on the results of an investigation into an occupational disease.

In the process of investigating any of the listed cases, first of all, it is necessary to compare this circumstance with the requirements set out in the instructional material. If there are shortcomings, then you should definitely take into account the reason why the unexpected happened;

- as prescribed by the state occupational safety inspector or other inspector. When inspecting an enterprise, violations are often identified, including in updating instructions.

The authorized inspection person has the right to issue an order regarding the need to reissue the document and verify compliance with this clause.

Checking and revising instructions

Every 5 years it is necessary to check the instructions for compliance with operating conditions. If it is current, its validity period is extended for the next 5 years by an appropriate order. Otherwise, the instructions are revised. In addition, early revision of the instructions is possible:

- in case of changes in working conditions;

- in case of purchasing new equipment and putting it into operation;

- when revising general intersectoral instructions on occupational safety;

- after emergency situations, cases of industrial injuries, occupational diseases.

General requirements for instructions

The instruction is valid for 5 years.

The development of occupational safety instructions is mandatory; this is determined by the legislative framework, including the system of occupational safety standards. The draft document is developed by the heads of enterprises, subject to legal review, signed by interested parties and approved by the employer.

The validity period of any instruction is no more than five years, and if the work is classified as hazardous, then no more than three. If the requirements have not changed during the specified period, then updating is still required.

HSE instructions are being developed by:

- for a certain type of work;

- regarding a certain profession.

Documents are developed taking into account the Rules, GOSTs, as well as standards and regulations in force at the enterprise during this period. Starting from the moment when the instruction for the enterprise was issued and put into effect by the Order, it automatically becomes a mandatory document for compliance with the standards specified in its content.

Every employee must know the location of the instructions, or the document must be in a known place, including at a labor protection stand. After updating, you should replace it with a new one.

Contents of the instructions

Contains the procedure for the employee before starting work.

The material reflects the conditions for accident-free and safe organization of the technological process, including the use of tools that comply with safety regulations, the use of personal protective equipment by the employee, and every detail must be taken into account.

To do this, before issuing instructions, it is necessary to carefully study the route of the technological process. This is necessary for the manager; if an employee violates safety requirements, then it is possible to find a link to what he did incorrectly.

The contents of the instructions cover:

- general provisions. Here is a list of regulatory documents adopted at the state level, as well as existing standards at the enterprise. The list of the latter is necessary so that there is no information contrary to current standards.

It is also necessary to indicate training, internship and rules for admission to the employee’s workplace. It is equally important to know in what cases an employee should not be allowed to perform production tasks;

- The following is a statement of requirements before starting work. This describes what the employee must do before starting work.

How often should labor safety instructions be reviewed?

In general, the frequency of revision of labor protection instructions is at least once every 5 years. For electric power enterprises, the standard period is once every 3 years, which can be explained by the increased risk of electric shock to workers.

The validity period of IOT labor safety instructions is valid as long as the employee has a need for it. This means that the life cycle is not limited to any specific period of time.

There are no mandatory requirements establishing a planned period for checking labor safety instructions. This means you can do it more often, but you can’t do it less often. If there are instructions for working with a hammer, then the requirements for the worker may be revised, but the process of working with this impact hand-held plumbing and assembly tool remains the same as a hundred years ago. The requirements for the employee must be specified in this document, therefore, if changes in legislation occur, a corresponding change must be made. If years later it will be possible to work with a hammer only for persons over 21 years of age, then such a requirement is indicated in the IOT no later than the day it comes into force.

Example. Let’s say that from July 1, 2031, changes will occur in the legislation on labor protection when working with a hammer - only persons under 50 years of age will be able to work with it. If the Rules come into force this year, then the employer is obliged no later than July 1 to familiarize the employee with these changes by conducting an unscheduled briefing on the already updated IOT. If the employee is notified of this change not on July 1, but, let’s say, on July 12, and during this period of time an accident occurs with an employee over 50 years old, the employer will bear administrative liability under Part 1 of Article of the Code of Administrative Offenses of the Russian Federation.