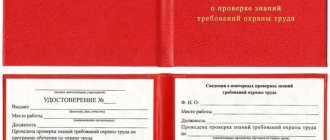

When conducting inspections, the State Labor Inspectorate (GIT) pays special attention to the availability and systematization of accounting and methodological documentation on labor protection at the enterprise, the correctness of its execution, keeping records of the issuance of personal protective equipment, and especially - working with occupational safety instructions for production workers, their issuance and registration in the appropriate journal.

How the “Journal of Occupational Safety and Health Instructions” should be formatted, what types of it should be in the working library of an occupational safety specialist, and what requirements are established for working with this document, we will describe in this article.

Why do you need a log of occupational safety instructions?

In accordance with the recommendations published by the Ministry of Labor of the Russian Federation, the log of labor protection instructions should be used to reflect the following information about instructions in the personnel service registers of the enterprise:

- date of registration of the document;

- names;

- date of approval by the head of the company;

- planned document verification period;

- information about employees responsible for registering instructions.

The data reflected in the labor safety instructions logbook is confirmed by the signature of the employee responsible for registering the instructions.

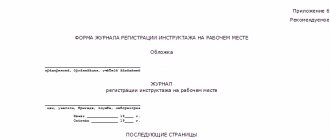

The recommended form of such a journal is recorded in Appendix 2 to the above-mentioned Methodological Recommendations of the Ministry of Labor.

A log of labor safety instructions developed for employees of a specific division of the company is stored, like the instructions themselves, with the head of the corresponding division (clause 9 of the Recommendations dated May 13, 2004). It is desirable that their storage location be optimal in terms of the company’s employees receiving prompt access to instructions (clause 10 of the Recommendations).

https://youtu.be/nVbwcRidcac

Types, form and purpose of the journal

The enterprise document flow system provides for the use of two types of Logbooks for recording instructions on labor safety and health:

- “Logbook of occupational safety instructions”;

- "Journal of issuing instructions on labor protection."

There is no standardized form of journals among the unified forms. However, the above appendices to the Resolution of the Ministry of Labor No. 80 established the indicative form and structure of these documents, which is recommended for use in all areas of production activity.

The log of labor safety instructions is used to register labor safety instructions developed and put into effect by order of the manager at the enterprise. It reflects accounting and registration information about the instructions and officials who carried out the accounting.

The journal for issuing instructions on labor protection is used to record the circulation of approved instructions within the enterprise, and to control the provision of regulatory documents to structural divisions.

The instruction log allows you to:

- streamline methodological documentation on occupational safety training;

- systematize documentation on occupational safety in structural divisions;

- plays an important role and is required by regulatory authorities when conducting investigations of insured accidents and injuries at work, since they make it possible to determine the limits of liability of officials and victims.

What is a journal for issuing occupational safety instructions?

The Ministry of Labor of the Russian Federation determines that instructions can be given to employees so that they can study the relevant documents as part of the initial briefing. Each fact of issuing instructions is subject to recording in a separate journal.

This log records:

- dates of issue of instructions;

- instructions numbers or other designations;

- titles;

- number of copies issued;

- Full name of the employees to whom the documents are issued.

Each employee who receives instructions signs in the journal.

The recommended form of this journal is approved in Appendix 3 to the Methodological Recommendations.

Why is it needed?

The journal is a way to reflect to whom and in what form labor safety instructions were issued. If an accident occurs at work due to failure to comply with labor safety instructions, the employee responsible for informing others may incur both administrative and criminal liability for failure to fulfill his duties. The completed log book impartially records who issued what and to whom, and whether briefing was carried out with a specific team member.

Having such proof of the fulfillment of their duties in hand, the manager, foreman or other person responsible for industrial safety minimizes their risk of going to prison by a court decision due to an accident.

Results

Labor safety instructions are an important document in the document flow of an enterprise, the provisions of which the employee must comply with. The Ministry of Labor of the Russian Federation proposes to record them using 2 types of journals - to record these documents and to record their provision to employees.

The first type of journal will allow the employer to control whether the personnel register contains instructions that are necessary at the enterprise, based on the specifics of the positions on the staffing table, and also how timely they are taken into account. The second log will help the personnel officer track which employees have already been familiarized with the labor protection instructions, and who still have to do this.

You can consider other useful nuances on labor protection in the articles:

- “Where to start with labor protection at an enterprise (nuances)?”;

- “What are the storage periods for labor protection documents?”;

- “Order on the creation of a labor safety commission - sample”;

- “How to draw up a labor safety action plan (sample)?”

Sources: Labor Code of the Russian Federation

You can find more complete information on the topic in ConsultantPlus. Full and free access to the system for 2 days.

How to fill out the Journal

If you have already taken the opportunity to download this occupational safety magazine, let's look at the order in which to work with it. When the Journal is approved by order, it acquires legal force and becomes an integral part of the company’s document flow. This means that the document:

- laced, sealed, and its pages are numbered. In this case, it does not matter whether the pages or sheets are numbered, the main thing is to make sure that if the sheet is torn out or cut out, it would immediately become noticeable. Page numbers can be written by hand, stamped, etc. If you find it easier to download an occupational safety journal than to type or buy one, prefer the .doc format, which can enable automatic page numbering, rather than the .pdf format, which does not. it is forbidden.

- filled in without missing lines. If at the end of the sheet there are 1-2 lines left that are inconvenient to fill out, they cannot be “extinguished” with the Latin letter “Z” or in another way. You'll have to work hard and fill it out. But there is also no need to try to fit what cannot be contained in one line - use as much space as you need for one entry.

- does not accept appliques, covering with corrector and other manifestations of “applied art”. If an error occurs while filling out the journal (it doesn’t happen to anyone), you need to cross out the entire line, make a note “erroneous entry,” sign, and start filling out the journal from a new line. If the error is found later, for example, in the 5th line, when the 24th line is already filled, the algorithm of actions does not change. The 5th line is crossed out, marked, and the information from it is entered into the 25th line. The crossed out and new lines can be marked somehow to make it easier to navigate after a while.

- filled with a pen that cannot be erased. Pencil, felt-tip pen, and other writing materials are prohibited.

Upon completion, the journal for issuing instructions on labor protection is stored in the archives of the enterprise for 10 years. Reason – clause 316a of the “List of standard management documents...” approved on October 6, 2000.

It is advisable to create a simple guide or instructions for filling out the Journal and paste it into the document (or print it on the back, for example). This will make it easier:

- introduction of a uniform procedure for filling out logs if there are several of them in one company.

- journaling. For example, when the names of instructions are quite long, it is advisable to shorten them and write them “in abbreviated form.” Since the state does not issue and, accordingly, does not require a uniform model for maintaining a Journal for issuing instructions on labor protection, in this way the person issuing the documentation has the opportunity to make his life easier on grounds not prohibited by law.

The employee who issues documents to workers or engineers makes entries in the logbook for issuing instructions on labor protection . It is advisable to prescribe this obligation in the order. Usually it is entrusted to specialists from the OT service and other engineers. The process is organized as it is advisable to do within a specific company, for example:

- occupational safety instructions are issued by a specialist from the occupational safety department to each worker personally. Magazine – one for the whole company;

- The occupational safety department transmits sets of instructions to company divisions, where persons appointed by order issue them to workers. One magazine is located in the OT department, the rest are at the issuing points.

Instructions are issued to workers in their main professions and part-time jobs. Entries are made upon issuance of each of them. If your company is offered to buy different occupational safety magazines for “main” workers and part-time workers, it is not necessary to follow such a recommendation. All entries “will not quarrel” within one journal.

Filling rules

The employer sets the registration procedure independently. The main thing is the presence of a personal signature of the person to whom the instructions are provided.

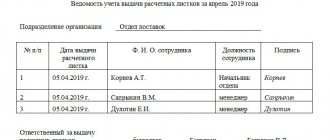

The actual issue must be recorded by the responsible person who enters information about:

- date of completion;

- FULL NAME. and positions of the person being instructed;

- the name of the issued document;

- number of copies provided;

- signatures of the employee who received the papers.

According to legal requirements, safety instructions are updated at least once every 5 years. If the process coincided with the fact of maintaining a previous journal, where the old format was recorded, information about the new edition is recorded opposite each column with such a document. When issuing several different papers to the same employee, information about each is entered on a separate line.

If there is an error in the format, the entire line should be crossed out and the correct information should be entered below. You cannot fill out the document with a pencil or skip lines. The electronic form is not possible, since it is necessary to record the entries with a personal signature.

What is it needed for?

A log of the issuance of instructions is kept to systematize the work of the labor protection unit at the enterprise.

Depending on the situation or time of implementation, the specialist responsible for carrying out preventive measures on occupational safety takes the appropriate instructions for conducting the briefing and makes a note in the logbook about the implementation of the measures. The instructions themselves are approved by an order of this type.

After the briefing, a note about the event is made in the log book, and the instructions are sent back to the storage location.

The journal is necessary since the instructions are internal documentation of the organization, subject to strict accounting. For their loss, the responsible specialist faces disciplinary measures.

In addition, any instructions are subject to updating over time, in accordance with current legislation.

they must be updated at least once every 5 years. If the renewal does not occur, then it is necessary to issue an order to extend the validity period.

The journal allows you to understand when and by whom the instructions were developed and adopted, when changes need to be made to them, who is responsible for conducting the instructions and what activities are provided for in each of its types.

All this makes it possible to streamline the work of the labor protection department and increase its overall efficiency, which has a positive effect on compliance with safety rules at work.