A fairly important issue in the organizational activities of enterprises is the issue of labor protection. Or rather, its organization, that is, the process of training employees and testing knowledge in this aspect. In the article we will talk about the procedure for testing workers’ knowledge of labor protection, consider the types and methods.

Today, all of the above issues are the responsibility of the employer, which is confirmed by Article 212 of the Labor Code of the Russian Federation. Moreover, this obligation does not depend on what legal form the employer belongs to and what agreement he has concluded with the employee.

The resolution of the Ministry of Labor regulates the procedure by which employees are trained and tested for knowledge of labor protection. According to it, the organization must develop a regulatory act that defines the procedure for conducting training, as well as testing knowledge. If the number of employees exceeds 50 people, the enterprise must organize a special service or introduce a job unit - a labor protection specialist.

If the number of employees is less than 50 people, then the employer independently decides whether to allocate an individual employee or carry out these activities himself.

For example, a director or entrepreneur can personally conduct training and take the exam. The Company may also engage a third party or individual specialist to provide services in this area. To do this, the organization will need to enter into a civil law agreement with this specialist.

Reasons for testing knowledge on labor protection

The inspections are carried out for the following reasons:

- When hiring for a new position, the manager must be trained in occupational safety within the first thirty days of the month.

- Without certification, an official cannot instruct subordinates.

- Requires knowledge of first aid and how to respond to emergency situations, including how to conduct investigations.

Studies

The requirements for studying regulations apply to foremen, site managers, technologists who have subordinates in the department, as well as those involved in the development of technological routes.

Procedure for testing knowledge

Representatives of blue-collar professions are checked by their immediate supervisors. The test is carried out on knowledge of rules and instructions, or any additional safety requirements. Moreover, the employee’s knowledge primarily depends on the knowledge of the manager who directly conducts the instruction. And when assessing an employee’s knowledge, the commission evaluates the level of knowledge of his manager as well.

| ★ Best-selling book “Accounting from scratch” for dummies (understand how to do accounting in 72 hours) > 8,000 books purchased |

Who conducts knowledge testing of labor protection requirements in the organization

Extraordinary test of knowledge on labor protection

At an enterprise, the organization of occupational safety training is carried out by the personnel department or a training center created at the enterprise. To administer the exams, a commission is created consisting of:

- chairman. This may be the chief engineer or the site manager;

- members of the commission. These are the main specialists, for example, the chief designer, technologist, mechanic, safety specialist or head of the safety department and others.

Important! It is necessary that the number of members, including the chairman, be odd, and they must have certification in the field of Health and Safety.

The company has the right to enter into an agreement with specialized training centers that will deal with this task if it is not possible to maintain a staff. You can take exams by taking tests through a computer program.

What types of checks

Who tests knowledge of labor protection?

Knowledge is checked by a specially created commission on labor protection within the company, this can be the head of the organization, his deputies, technical director, chief engineer, labor protection specialists, persons responsible for the state of labor protection who have been trained in labor protection in special training centers. By the way, do you know without which document occupational safety training is impossible? And we know and will tell you in more detail about this document in this article.

After completing the training, such specialists and managers have the right to train workers and test the knowledge of labor protection of workers who are not responsible for organizing labor protection work. The knowledge testing commission is created by order of the head of the organization and must consist of at least three people.

Types of occupational safety knowledge tests

When is an extraordinary test of personnel knowledge on electrical safety carried out?

There are three types of checks:

- Primary (after taking up a leadership position).

- Repeated or extraordinary.

- Periodic or regular.

Note! The first of these is carried out in cases where the employee has re-entered work. When transferring to another place of work, certification will also be required again.

Regular (periodic)

Periodic certification is carried out at the enterprise. The purpose of it is to test the knowledge of workers after the expiration of the certificate, which is at least three years, unless there are additional requirements. For this:

- An administrative document is issued.

- A training group is created and staff are trained.

- Exams are taken by a commission or through computer testing.

About training

The main task of conducting the next certification is to update previously acquired knowledge, taking into account all amendments to the main regulatory and legislative acts.

Extraordinary inspections

Certification is carried out directly at the enterprise by the labor inspectorate for occupational safety or by government agencies, depending on the severity of the incident.

Reasons for surrender:

- If amendments have been made to the regulatory documentation or local acts of the organization containing health and safety requirements.

- If new equipment that was not previously purchased by the enterprise is put into operation.

- When changes are made to routes.

- If an employee is transferred to another position, and the functional responsibilities assigned to him require additional skills and knowledge.

- If labor safety norms and rules were clearly violated and the violations were prescribed in orders from supervisory authorities, labor inspectorates or enterprise management.

- The theoretical training of personnel was considered insufficient.

- If violations have been committed more than once.

- If there was a break in the work at the position held and this period is more than one year, it is possible to take the exam later.

Health and safety

Knowledge of standards is tested by a commission or by answering questions from tests.

Commission requirements

The procedure and scope of an extraordinary knowledge test is determined by the party that initiated this procedure. Passing the exams is preceded by training according to a program approved by the head of the enterprise.

Certification is carried out by a commission consisting of at least 5 people. The composition of the commission is established by internal order. In some cases, the chairman is the person responsible for the electrical facilities. But any person with 4th group of security clearance (up to 1000 v) can be appointed to this position. At facilities with electrical equipment over 1000 V, the head of the commission can only be an employee with group 5.

All members of the commission are required to have an electrical safety clearance group and successfully pass certification by the energy supervision authorities. Knowledge testing can be carried out in production, provided that the head of the commission and at least two of its members have already been certified by Rostechnadzor.

Educational experts will tell you more about the extraordinary knowledge test.

The procedure for conducting occupational safety knowledge tests

Protocol for testing knowledge on labor protection

The organization conducts a test of knowledge on occupational safety, in accordance with the current regulations or other local act of the enterprise.

The procedure is as follows:

- Heads of individual departments submit applications to the training center at the end of the next year.

- The training center creates a training schedule.

- If necessary, commission members whose certification period has passed are tested.

- Curricula or programs are prepared and agreed upon with the labor inspectorate and trade union organization.

- Administrative documents on certification are issued.

- Workers prepare themselves and undergo testing or take oral exams.

- The results are documented in a protocol, and then certificates are issued.

For employees

Completion of knowledge tests in the field of occupational safety for workers is carried out both by profession and type of activity, for example:

- For safe work at height, if you need to work on the roof or in the cradle of a lift.

- For working with hydraulic and mechanical engineering, if, according to duties, it is necessary to move cargo from one place to another.

- When working with pneumatic tools.

- When working with excess pressure.

About knowledge testing

Note! Knowledge and skills testing is carried out once a year; if an employee does not pass timely certification, then he cannot be allowed to work.

For managers

Testing knowledge in the field of health and safety is regulated by the regulations or standards of the enterprise. After the order is issued, a training group is created or officials independently study the rules. After which testing is carried out on a computer or the exam is accepted by a commission.

OT knowledge is tested:

- in preschool educational institutions (preschool institutions);

- public services;

- offices;

- industrial enterprises and private companies;

- other structures whose activities are subject to the requirements of the rules.

How is training carried out?

Training and testing of knowledge on labor protection

Occupational safety training is provided to:

- Employers, their deputies in charge of labor protection issues, deputy chief engineers for labor protection, employers - individuals, other persons engaged in business activities.

- Managers, specialists, engineering and technical workers who organize, manage and carry out work at workplaces and in production departments, as well as control and technical supervision of work.

- Pedagogical workers of educational institutions of primary, secondary, higher, postgraduate and additional professional education - teachers of the disciplines “Occupational Safety”, “Life Safety”, “Safety of Technological Processes and Production”.

- Organizers and supervisors of students' practical training.

- Occupational safety specialists.

- Employees who are assigned by the employer the responsibility for organizing work on labor protection.

- Members of labor protection committees (commissions).

- Authorized (trusted) persons for labor protection of trade unions and other representative bodies authorized by employees.

Managers and specialists of organizations undergo special training in labor protection within the scope of their job responsibilities upon entering work during the first month, then as necessary, but at least once every three years.

Newly appointed managers and specialists of the organization are allowed to work independently after their employer familiarizes them with job responsibilities, including labor protection, with the local regulations in force in the organization that regulate the procedure for organizing work on labor protection, and working conditions at the facilities entrusted to them ( structural divisions of the organization).

Labor protection training for managers and specialists is carried out according to relevant labor protection programs directly by the organization itself or educational institutions of vocational education, training centers and other institutions and organizations engaged in educational activities (hereinafter referred to as training organizations), if they have a license to conduct educational activities. activities, teaching staff specializing in the field of labor protection, and the corresponding material and technical base.

Managers and specialists of the organization can undergo training in labor protection and testing of knowledge of labor protection requirements in the organization itself, which has a commission for testing knowledge of labor protection requirements.

Occupational safety training for managers and specialists in an organization is carried out according to occupational safety training programs developed on the basis of sample curricula and occupational safety training programs approved by the employer.

In the process of training managers and specialists in occupational safety, lectures, seminars, interviews, individual or group consultations, business games are conducted; elements of self-study of the occupational safety program, modular and computer programs, as well as distance learning can be used.

Labor protection training for managers and specialists of organizations is carried out while improving their qualifications in their specialty.

Managers and specialists of organizations undergo regular testing of knowledge of labor protection requirements at least once every 3 years .

Managers and specialists of organizations who have not passed the knowledge test of labor protection requirements during training are required to undergo a second knowledge test no later than one month. The issue of suitability for the position held by managers and specialists who have not passed the labor safety knowledge test for the second time is decided by the head of the enterprise in the prescribed manner.

Rules for testing workers' knowledge of labor protection

Certification of workers is regulated by local regulations of the enterprise.

This is done in the following sequence:

- The organizational structure appoints a person responsible for conducting and monitoring certification.

- Workers are given time to prepare without interruption from performing the production task.

- At a manufacturing enterprise, a commission is created to accept tests, and its members must have knowledge in the field of occupational safety and have documents.

- Exams are taken at the time specified in the administrative document.

- The results are recorded and a certificate is issued.

Note! Programs and questions must be prepared earlier, signed by the head of the structure and agreed upon with the inspector.

When is an extraordinary knowledge test carried out?

The reasons may be as follows:

- the entry into force of changes in existing rules or regulations;

- commissioning of new electrical installations and devices or carrying out reconstruction, adjustment of technological and/or electrical circuits;

- assigning an employee to a new position, changing a structural unit or place of work, if the employee is assigned new responsibilities that require additional knowledge on electrical safety;

- if employees violated the requirements of regulatory legal acts when working with electrical equipment;

- at the initiative of the person responsible for electrical equipment;

- according to the order of representatives of supervisory or control authorities;

- according to the conclusion of the commission, which investigated violations in the operation of electrical installations or accidents with employees of the organization while performing professional activities;

- increasing the electrical safety clearance group;

- receiving an unsatisfactory grade during a scheduled knowledge test;

- a break in professional activity lasting more than 6 months.

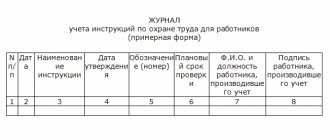

Based on the results of certification, employees are issued certificates. An entry is made in a journal of the established form, stamped and signed by all members of the commission.

Frequency of testing knowledge on labor protection

- The frequency of testing acquired knowledge on labor protection is clearly specified in regulatory documents:

- It is established for officials, engineers and specialists to undergo training at least once every three years, unless a more frequent inspection period is established.

- For persons whose positions are not managerial - once a year.

- If there are violations or insufficient knowledge in the field of occupational safety, changes in technological routes or equipment modernization, knowledge is checked unscheduled.

In order to organize and guide the implementation of this type of work, it is necessary to be guided by the requirements of the rules and other documents regulating the passing of OT tests.

Testing the knowledge of electrical workers is divided into primary and periodic (regular and extraordinary).

The initial knowledge test is carried out for workers who first entered a job related to the maintenance of electrical installations, or when there is a break in knowledge testing for more than 3 years.

The next knowledge test for electrical personnel directly organizing and carrying out work on servicing existing electrical installations or performing electrical installation, adjustment and repair work in them, as well as for personnel who have the right to issue orders and orders, should be carried out once a year.

The time of the next test is set in accordance with the date of the last knowledge test.

An extraordinary knowledge test is carried out regardless of the date of the previous test:

— upon the introduction of new or revised rules and regulations;

— when installing new equipment, reconstructing or changing electrical and technological circuits;

— in case of violation by employees of the requirements of regulations on labor protection;

— at the request of state supervisory authorities;

— according to the conclusion of commissions that investigated accidents with people or disruptions in the operation of an energy facility;

- when increasing knowledge to a higher group;

— after receiving an unsatisfactory grade in a knowledge test;

- upon appointment or transfer to another job, during a break in work in this position for more than 6 months.

Organizational measures to ensure the safety of work in electrical installations (MPOT clause 2.1.1). Organization of work performed in the order of routine operation according to the list (MPOT section 2.4).

Small-scale types of work performed during a work shift and permitted for production in the order of routine operation must be contained in a list of works developed in advance and approved in the prescribed manner.

The following requirements must be met:

— work in the order of current operation (list of works) applies only to electrical installations with voltages up to 1000 V;

— the work is performed by operational or operational-repair personnel on the equipment or area assigned to these personnel.

Preparation of the workplace is carried out by the same employees who subsequently perform the work. Work in the order of routine operation included in the list is permanently permitted, for which no orders or targeted instructions are required.

The work performed in the course of routine operation in electrical installations of instrumentation and automation with voltages up to 1000 V includes:

— replacement of signal lamps on instrumentation and alarm panels;

— replacement of diagrams and writing units on recording instruments;

— cleaning of panels of instrumentation and control boards from the front side;

— cleaning of premises behind instrumentation and automation panels.

How is the inspection recorded?

The certification is recorded in the protocol. The document reflects the following information:

- Serial number.

- Last name and initials (in full) of the person who passed the test.

- Name of the employee's position.

- The identification number is indicated.

- Reason for certification.

- Mark on passing or failing the exam.

Note! The protocol is signed by the commission members and the chairman. You can draw up the document on a computer, or you can do it yourself. This is performed by specialists from the training center or personnel department employees. The protocol is drawn up in two or more copies, some of which are kept by the organizers, and others are transferred to the enterprise and other structures from which the authorized representative was present at the certification.

Frequency and procedure for testing knowledge of electrical personnel

Frequency and procedure for testing knowledge of electrical personnel. In order to test the knowledge of the electrical and electrical engineering personnel of the organization, the head of the Consumer must appoint, by order of the organization, a commission consisting of at least five people.

The chairman of the commission must have electrical safety group V for Consumers with electrical installations with voltages up to and above 1000 V and group IV for Consumers with electrical installations with voltages only up to 1000 V. All members of the commission must have an electrical safety group and pass a knowledge test in the commission of the state energy supervision body.

It is allowed to test the knowledge of individual members of the commission on the spot, provided that the chairman and at least two members of the commission have passed a knowledge test in the commission of the state energy supervision authorities.

At least three members of the commission must be present during the knowledge test, including the chairman (deputy chairman) of the commission.

Testing the knowledge of consumer employees, the number of whom does not allow the formation of knowledge testing commissions, should be carried out in commissions of state energy supervision bodies.

Testing of personnel knowledge is divided into primary and periodic (regular and extraordinary).

The initial knowledge test is carried out for workers who first entered work related to the maintenance of electrical installations, or when there is a break in knowledge testing for more than three years.

The next inspection is carried out at the following times:

- for electrical personnel directly organizing and carrying out work on servicing existing power plants or performing adjustment, electrical installation, repair work or preventive tests in them, as well as for personnel who have the right to issue orders, orders, and conduct operational negotiations - once a year;

- for administrative and technical personnel not belonging to the previous category, as well as for labor protection specialists admitted to inspecting installations - once every 3 years.

An extraordinary knowledge test is carried out regardless of the date of the previous test:

- when new or revised rules and regulations come into effect for the Consumer;

- when installing new equipment, reconstructing or changing the main electrical and technological circuits (the need for an extraordinary check in this case is determined by the technical manager);

- upon appointment or transfer to another job, if new responsibilities require additional knowledge of rules and regulations;

- in case of violation by employees of the requirements of regulations on labor protection;

- at the request of state supervisory authorities;

- according to the conclusion of the commission that investigated accidents with people or disruptions in the operation of an energy facility;

- when increasing knowledge to a higher group;

- after receiving an unsatisfactory grade in a knowledge test;

- if there is a break in work in this position for more than 6 months.

An extraordinary inspection , carried out at the request of state supervision and control authorities, as well as after accidents, incidents and accidents, does not cancel the timing of the next scheduled inspection and can be carried out in a commission of energy supervision authorities.

Employees who have the right to carry out special work must have a note about this in their certificate. Special work includes: steeplejack work, work under voltage on live parts, testing equipment with high voltage (the list of special work can be supplemented by instructions from the employer).

Electrical safety tests are available on the Profitesta Olympox to prepare for the certification of managers and specialists, as well as to prepare electrical personnel for the exam for the group allowed to work independently .

Legislative framework for drafting

It is important to know that documents such as protocols and certificates are clearly filled out, since documents may be requested during the investigation of an emergency situation or accident.

The forms of the above documents can be taken from the Consultant system, or they can be developed and approved by an internal act.

Responsibility for violation of the procedure for training and testing knowledge of labor protection requirements for workers lies with the administration. If the requirements are not met, the management of the organization is subject to a fine of 30 to 40 thousand rubles with disqualification from their position.

The management of organizations is obliged to conduct and monitor the testing of knowledge of occupational safety workers in offices and industrial enterprises.

Organization of training for blue-collar workers

- primary training in safe methods and techniques for performing work, providing first aid to victims - within a month after the worker is hired or transferred to another job. And if the work involves harmful and (or) dangerous working conditions, then the employer must also organize an internship for the new worker at the workplace and pass exams;

- periodic training in safe methods and techniques for performing work and testing knowledge of labor protection requirements for workers with harmful and (or) dangerous working conditions;

- periodic, at least once a year, training of all workers to provide first aid to victims.