Who passes the knowledge test

There are a total of 5 tolerance groups in this area. The first group is assigned to personnel not directly related to the maintenance of electrical installations, while their activities are, in one way or another, dependent on electrical appliances.

These personnel are called non-electrical personnel. This includes premises cleaners, accountants and other persons whose work involves reading and entering information onto a PC.

Employees are required to have basic knowledge of electrical safety, including how to provide first aid until emergency services arrive.

List of categories of workers who are assigned electrical safety groups 2 to 4:

- Administrative and technical. These are safety engineers, technologists, and designers related to electronic media.

- Operations and repair personnel. These are electricians who repair electrical installations.

Heads of departments and individual sections should have electrical safety groups no lower than those of their subordinates.

Who belongs to electrical and non-electrical personnel

ETP (electrical technical personnel) is a category of workers who operate electrical installations and carry out commissioning, installation work, maintenance and repair of electrical equipment.

This category includes:

- management of electrical installations - administrative and technical personnel.

- direct performers - operational, maintenance and repair personnel.

ETPs are divided into personnel of consumer organizations and personnel of electric power industry organizations.

Electric power enterprises include hydroelectric power plants, thermal networks, electrical networks and substations, electricity sales companies and other enterprises that not only generate electric current, but also transport and distribute it.

Consumers include all other enterprises and individual entrepreneurs who buy current to solve their business problems.

There is another fairly large category of workers who are assigned group I according to ES , but they do not belong to the ETP - we will talk about their training separately in this article.

Types of electrical safety knowledge tests

Electrical safety knowledge is divided into the following types:

- Primary. If an employee has re-entered work, then he cannot be allowed to perform tasks independently, since he does not know the technical process. If the break in work is more than three years, then you will need to undergo training again.

- The next one. After the expiration date, the knowledge test must be carried out again. The order of priority is established by rules depending on the categories of workers.

- Extraordinary. When changing the sequence of technological operations; the introduction of new rules, instructions, as well as after changes to existing ones; upgrading obsolete equipment or purchasing new equipment; at the request of inspectors, including representatives of Rostechnadzor; in case of violation of OT requirements; Based on the results of the commissions’ conclusions and other changes, an unscheduled test of employees’ knowledge is carried out.

Walkthrough

Certification for each employee is determined depending on the position held, experience and skills. For any employee, the scope of the inspection and the requirements for it are established by the manager. You must first agree on the requirements and documents, the work with which is specified in the employee’s job responsibilities.

Note! After this, an exam is conducted and the results are recorded in a special journal. As a result of successfully passing the exam, the employee is issued an appropriate certificate.

Frequency of testing knowledge on electrical safety

As noted earlier, verification is divided mainly into regular and primary.

Deadlines for recertification:

- If an employee returns to the workplace, he must be certified within a month.

- If there was a break in work, then after three years the time comes for certification again.

- Once a year, employees involved in repairs or servicing electrical consumers are recertified.

- Administrative and technical personnel undergo inspection every three years.

If an extraordinary certification is required, an additional commission meets and conducts a knowledge test.

Requirements for the employer

The employer is responsible for ensuring that all equipment operates correctly and correctly. It must be serviced and inspected on time. The employer carries out periodic certification and briefings, checking compliance with all rules and safety requirements when working with electrical installations.

Certification of employees for knowledge of the correct operation of electrical machines and installations should be carried out at certain intervals for each group, depending on their qualifications. For this purpose, a commission is assembled and an exam is held. Based on its results, an entry is made in the journal and a document is issued to the specialist.

Procedure for testing knowledge

The organization of work at the enterprise to test the knowledge of employees is carried out as follows:

- At enterprises, an administrative document is issued, which stipulates all the nuances of the inspection, and the document must comply with the requirements of the rules.

- If necessary, training is organized (during initial certification).

- Time for preparation is provided according to the developed tickets.

- Exams are accepted by a commission at the enterprise.

- Based on the results of the inspection, a protocol is drawn up, in one of the columns of which it is written whether the tests were passed or failed.

- If the knowledge test passes with a positive mark, then the information is entered into the certificates.

Then you can work as intended.

If the exams are not passed, then additional time is assigned for retraining, and the commission meets again to accept tests. If the exams are not passed, the question of suitability for the position may be decided again. Programs and tickets must be developed in advance and approved by the head of the training center. The form of the protocol is also developed separately and approved by the regulatory act of the association.

How often is the group confirmed?

The next test of knowledge of personnel with qualification group I is carried out annually.

The next test of knowledge of personnel with qualification groups II-V is carried out:

- for electrical personnel directly organizing and carrying out work on servicing existing electrical installations or performing adjustment, electrical installation, repair work or preventive tests in them, as well as for personnel who have the right to issue orders, orders, and conduct operational negotiations - once a year;

- for administrative and technical personnel not belonging to the previous group, as well as for labor protection specialists authorized to inspect electrical installations - once every 3 years.

Important! Do not miss the deadlines for the next electrical safety certification, since if there is a break between knowledge tests of more than three years, the group is lost irretrievably and you will have to start over again, with the assignment of admission group II (clause 1.4.19. Regulation dated January 13, 2003 N 6 PTEEP) .

When changing place of work, the employee must undergo an extraordinary re-certification to confirm the current group and receive a certificate indicating the new place of work and position. The certificate from the previous place of work is not valid at the new place of work.

An employee can take the next knowledge test either at a training center or at a commission formed within the company.

The commission must consist of five people, three of whom (including the chairman) must be certified by Rostechnadzor. As a rule, the chairman of the commission is the person responsible for electrical equipment.

When conducting a knowledge test, at least three members of the commission must be present, incl. chairman

Knowledge testing is carried out according to developed and approved programs, taking into account the specifics of the enterprise’s activities.

Confirmation of the admission group of the person responsible for electrical equipment is carried out only by the Rostechnadzor commission.

Creation of an attestation commission

At enterprises where it is required to test knowledge in the field of electrical safety, a certification commission is created or contracts are concluded with a third-party organization that has the right to conduct certification.

The composition of the commission is determined by order of the enterprise; the commission includes:

- Chief Power Engineer. This is an official who has the highest electrical safety group. Group can be 4 if the facility operates technical devices with voltages up to 1000 V, and also 5 - if the voltage of power equipment is over 5000 V.

- Deputy managers or chief engineer, safety engineer, these categories of employees are required to have at least 4 access group.

- Heads of facilities in this division.

What are the requirements for commission members:

- electrical safety certification must not be expired;

- it is necessary to be certified at Rostechnadzor or with a representative of this organization directly at the enterprise;

- You must have identification on hand.

The commission is created from an odd number of members; this requirement must be fulfilled, since when resolving controversial issues, voting will be required and this is how it can be determined whether the employee is certified or not.

The organization independently chooses who specifically to include in the Certification Commission (AC).

Who is the person responsible for electrical equipment?

The work of personnel in the company is inextricably linked with the use of equipment powered from the mains. Workers use power tools - hammer drills, grinders, and portable lamps. Office workers perform work duties surrounded by computer equipment and peripheral devices.

In order to organize control over the safe operation of electrical equipment, each company must appoint a person responsible for electrical equipment (clause 1.2.3 Regulation of January 13, 2003 N 6 PTEEP).

The responsible person ensures that the necessary measures are taken to allow personnel to work in electrical installations, controls the implementation of scheduled preventive maintenance, periodic testing of protective equipment, and ensures the uninterrupted operation of electrical equipment.

If the company has electrical installations with a capacity of 10 kVA or higher, a deputy responsible for electrical facilities is also appointed by order of the manager.

The person responsible for electrical equipment and his deputy are appointed by order of the manager.

A sample order is shown in the figure:

The person in charge of electrical equipment and his deputy must have clearance group IV if the company has electrical installations with voltages up to 1000 V and tolerance group V if there are electrical installations with voltages above 1000 V (clause 1.2.7. Regulation dated January 13, 2003 N 6 PTEEP).

The regulatory document allows not to appoint a person responsible for electrical equipment in cases where the company does not have equipment powered from a network with a voltage higher than 380 V (clause 1.2.4 Resolution No. 6 PTEEP dated January 13, 2003).

In this case, the manager assumes responsibility for the safe operation of electrical installations. However, such a decision requires approval from the territorial bodies of Rostechnadzor.

What is electrical safety training and who provides it?

Assignment to group I is carried out in the form of instructions; special training for personnel is not required.

The instruction is conducted by a company employee with an electrical safety group of at least III. Usually this is the person responsible for the company's electrical facilities.

Registration of assignment of group I is carried out in the “Register of assignment of group I for electrical safety to non-electrical personnel”.

A sample of a completed journal is shown in the figure.

To initially obtain the II group of admission, personnel with secondary education or without secondary education must undergo electrical safety training for at least 72 hours and pass exams at the certification commission of Rostekhnalzor.

Those who successfully pass the knowledge test are assigned admission group II and issued a certificate in the established form.

Requirements for employees to be tested

What are the requirements for a manager?

- The electrical safety group must correspond to the voltage consumed.

- An official who is entrusted with responsibility for electrical equipment is appointed to the position of chairman.

- The inspection group must not be lower than that of the employee being certified.

The following requirements apply to examiners:

- Mandatory certification in the territorial division of Rostechnadzor. It is allowed for two employees to undergo a knowledge test at the state energy supervision, and all the rest at the enterprise itself.

- If the structure of the organization is large enough, then such commissions are created at each facility. This makes it more convenient to work and carry out checks.

- The AC may include representatives of supervisory authorities; they are included by agreement.

- If the enterprise employs a small number of employees, then it is enough to take exams directly at Rostechnadzor, and the creation of commissions will not be advisable.

Formation of a commission at an enterprise

For the purpose of conducting certification within the organization, it is necessary to assemble a commission. In this case, there are requirements that establish the required number of workers with the required qualifications. All possible requirements and conditions are specified in the PTEEP. They state that the minimum number of examiners should be five or more.

Group 2 on electrical safety: test, knowledge test, requirements

The commission may consist of highly qualified employees. After the meeting of the necessary commission, a document is created, which is certified by the head of the organization. This allows the certification to begin.

Note! The commission is created for a specified period during which its powers last. After the deadline, you must submit an activity report to the director.

Test results

If the check is carried out, its results must be recorded. This will be a kind of report on the work done.

For this purpose, a protocol is provided that reflects the following information:

- full name of the enterprise where the exams were taken;

- what is the name of the document and its serial number;

- where and when the knowledge test was conducted (for example, in the meeting room, at 14.00);

- information about officials who are members of the AC;

- information about employees who need to undergo certification;

- what inspection results are noted;

- conclusion determined by commission.

The protocol is signed by the commission members and approved by the chairman, after which certificates are issued based on this document.

https://youtu.be/N4cuzTKhBmc

How to improve the electrical safety group?

Testing employees' knowledge is divided into primary and periodic (regular and extraordinary).

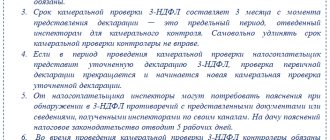

An initial knowledge test is carried out for workers who first entered a job related to the maintenance of electrical installations, or when there is a break in knowledge testing for more than 3 years; next - in the order established in clause 1.4.20. Etc. dated January 13, 2003 N 6 PTEEP); and extraordinary - in the manner established in clause 1.4.23. Etc. dated January 13, 2003 N 6 PTEEP).

clause 1.4.20. The next inspection should be carried out within the following periods:

- for electrical personnel directly organizing and carrying out work on servicing existing electrical installations or performing adjustment, electrical installation, repair work or preventive tests in them, as well as for personnel who have the right to issue orders, orders, conduct operational negotiations - once a year;

- for administrative and technical personnel not belonging to the previous group, as well as for labor protection specialists authorized to inspect electrical installations - once every 3 years.

The time of the next test is set in accordance with the date of the last knowledge test.

clause 1.4.23. An extraordinary knowledge test is carried out regardless of the date of the previous test:

— when the Consumer introduces new or revised norms and rules;

— when installing new equipment , reconstructing or changing the main electrical and technological circuits (the need for an extraordinary check in this case is determined by the technical manager);

- upon appointment or transfer to another job, if new responsibilities require additional knowledge of rules and regulations;

— in case of violation by employees of the requirements of regulations on labor protection;

— at the request of state supervisory authorities;

— according to the conclusion of commissions that investigated accidents with people or disruptions in the operation of an energy facility;

— when increasing knowledge to a higher group;

— when testing knowledge after receiving an unsatisfactory grade;

- if there is a break in work in this position for more than 6 months.

clause 1.4.38. Based on the results of testing the knowledge of the rules for constructing electrical installations, these Rules, safety rules and other regulatory and technical documents, an electrical safety group is established for electrical and electrical engineering personnel.

Who should be trained

The basis for conducting training for various categories of employees of enterprises and organizations are the following documents:

- Order of the Ministry of Labor No. 328n dated July 24, 2013 “On approval of the Rules for labor protection during the operation of electrical installations”,

- Order of the Ministry of Energy No. 6 of January 13, 2003 “On approval of the Rules for the operation of consumer electrical installations.”

Training is required for all employees whose work involves equipment that consumes electrical current:

- non-electrical personnel - workers not directly associated with electrical installations, but who are at risk of electric shock;

- electrical technical personnel - engaged in installation, adjustment, maintenance, repair of electrical installations and manages their operating mode, divided into: administrative and technical,

- operational,

- operational repair,

- repair.

- electrotechnological installations (electric welding, electrolysis, electrothermy);

Taking into account their job responsibilities, specialists undergo a certain type of training and, after testing their knowledge, receive the electrical safety clearance required for work.

Training program

Depending on the assigned group, the electrical safety training program may include:

- fundamentals of legislation on technical regulation and industrial safety;

- general labor protection rules, including rules for admission to work, regulatory documents on the design and safe operation of electrical installations;

- basics of electrical engineering;

- rules for releasing the victim from the effects of electric current, providing first aid to victims at work;

- rules for the use and testing of protective equipment;

- other rules, regulatory and operational documents of the enterprise.

How and with what frequency knowledge of labor protection and electrical safety is checked

Dear readers! Our articles talk about typical ways to resolve legal issues, but each case is unique.

If you want to find out how to solve your particular problem, please use the online consultant form on the right or call ext. 738. It's fast and free!

Activities and methods aimed at protecting people from electric shock during the operation of electrical installations are united by the general concept of electrical safety. Frequency testing of electrical safety knowledge and training are important to ensure that only qualified, competent employees with the appropriate knowledge and safe work skills are allowed to work.

Electrical safety certification procedure

|

From Administrator in Articles

Comments

Electrical safety rules exist to ensure reliable, safe and rational operation of electrical installations and their maintenance in good condition. The operation of electrical installations should be carried out only by trained personnel who have the appropriate group of permission to work with electrical installations.

In accordance with the requirements of paragraph 14 of the Regulations on the industry commission of the Federal Service for Environmental, Technological and Nuclear Supervision for testing knowledge of norms and rules in the field of energy supervision, approved by Order of Rostechnadzor dated May 28, 2008 No. 362a (hereinafter referred to as the Regulations) , the basis for organizing the verification knowledge of norms and rules is the submission of an application to send an employee for a knowledge test to the sectoral territorial commission of the Rostechnadzor body.

The application is submitted to the address of the territorial body of Rostechnadzor in a way that allows you to establish the date and fact of sending and receiving documents.

The following documents must be submitted along with the application:

for employees working at energy facilities (energy supplying organizations), - an extract from the logbook for testing knowledge of the rules of work in electrical installations (Appendix 5 of the Rules for labor protection during the operation of electrical installations, approved by Order of the Ministry of Labor of Russia dated July 24, 2013 No. 328n (hereinafter referred to as the Rules)) , and a protocol for testing knowledge of the rules of operation in electrical installations (Appendix 4 of the Rules);

for employees of organizations purchasing electrical energy (consumers of electrical energy) - an extract from the logbook for testing knowledge of the rules of work in electrical installations (Appendix 6 of the Rules).

Extracts must be certified by the organization that issued the above documents.

Organization of inspection

https://youtu.be/xmAWbz1xkAU

The verification is carried out by the certification commission. The latter is organized for a limited period. Upon completion of its activities, the commission must submit a report on its work to the manager. Its composition is determined by the administration of the enterprise.

It is the commission that needs to prepare a schedule for conducting certification. It is approved by the head of the company. Based on the schedule, knowledge is tested. Not all commission members may be present during the actual certification process. However, there must be a chairman or his deputy present.

Checks are carried out on an individual basis. That is, each individual employee undergoes certification. The list of knowledge that will be tested is established by the head of the organization. The nature of the questions depends on these circumstances:

- Job responsibilities.

- The nature of the work performed.

- List of used regulatory documentation.

Usually, knowledge about the operation of electrical installations, electrical safety rules, and rules for checking the performance of equipment are tested. The employee's knowledge of first aid procedures for electrical accidents is usually confirmed.

Verification can be carried out in various formats. For example, this could be a classic format with exam papers. The examiner may be an electrical safety specialist. But you can replace it with computer programs.

If an employee passes the exam, he is issued a certificate of this. If he fails, recertification is scheduled.

The commission is created on the basis, inter alia, of the Order of the Ministry of Energy “On Approval of Rules” No. 6 of January 13, 2003. A commission can be organized only if the enterprise has enough employees with the required qualifications.

Its minimum composition is 5 people. The creation of a commission must be confirmed by an order from the head. Participants receive full certification authority only when this order is signed.

It is required to appoint a chairman of the commission. It must meet a number of requirements. In particular, only an employee with clearance group 5 can become a chairman. Exception: the test is performed for persons working with equipment up to 1,000 Volts. In this case, it is enough for the chairman to have clearance group 4.

We invite you to familiarize yourself with a sample MTS fraud claim

IMPORTANT! The chairman cannot have an access group that is smaller than that of the employee undergoing verification.

How a group is assigned

Certification for permission to work in the second electrical safety group is carried out in accordance with regulations. For this purpose, a commission is created on the basis of an administrative document. Each member of the AC must have permission recorded in the certificate. A time is set for taking the exams and the opportunity to prepare is provided.

Where do they take the electrical safety group?

The exam is carried out at the enterprise, but only if there is a certificate to conduct it. If it is not possible to take tests on your own, then certification is carried out in specialized training centers that have permission to engage in this type of activity.

Who can take the exam

Knowledge testing is carried out on a commission basis. The minimum number of members must be at least three, including the chairman.

Basic conditions for creating a commission:

- If there are electricity receivers with a voltage of less than 1000 V, the chairman must have at least clearance group IV.

- If the voltage indicator is more than 1000 V, then the group assigned to the chairman must be at least V.

- The commission may include production site managers and occupational safety specialists.

- All members of the commission must have an electrical safety group of at least second.

- Certification of the chairman and members is carried out at Rostechnadzor or at the enterprise, but in the presence of an inspector.

Exam program for obtaining admission

Training is carried out according to the Program developed at the enterprise and approved by Rostechnadzor.

The training includes the following materials:

- Primary requirements.

- How is permission to work granted?

- List of technical documentation required for work.

- Concepts about electrical safety groups.

- Occupational health and safety during work.

- Actions in case of emergency situations: accident, incident, accident.

- Provide first aid until medical professionals arrive.

When preparing a program, you can use a standard one, and also take into account the specific capabilities of the organizational structure.

Training

Electrical Safety Exam

Knowledge is checked by commission and admission options are as follows:

- In the enterprise organization commission.

- In a specialized training center, and the composition should include an inspector from Rostekhnadzor, who monitors the safety during the operation of technical devices.

- Directly in RTN, geographically located.

The management of the organization appoints commission members to conduct certification. The chairman, as a rule, is the employee responsible for the energy management of the facility. All members of the commission must have certificates with a mark of certification.

Knowledge testing is carried out using tickets specially designed for the Training Program. Upon successful completion of the test, an entry is made in the protocol and a certificate is issued. If the certification is repeated, then a record of its completion is made.

Knowledge test result

The results of testing the knowledge and skills of employees are prepared according to the following algorithm:

- The training center of the enterprise or a third-party organizational structure approves the form of the protocol and certificate. The established forms of documents are placed in regulations.

- Information about passing tests is entered into the journal.

- Data on the inspection performed are recorded in the protocol: the employee’s surname and initials, job title, which electrical safety group was assigned, when the next certification is required.

- The results of passing the tests are entered in the certificate: the document number, the name of the enterprise, the surname and initials of the employee in full, his position when the document was issued are indicated; the date of the knowledge assessment, the reason for the event, which group was assigned, the assessment, the deadline for the next certification is indicated.

The certificate is issued to the employee.

Training and knowledge testing in

Our educational and methodological center offers all the necessary programs on electrical safety - from initial briefings to obtaining group V approval with the right to measurements and tests, as well as professional retraining under the Electrical Engineering program.

Upon successful completion of the certification task, you will receive a certificate indicating the appropriate admission group or a diploma of professional retraining, depending on the course taken. Information about the completion of training is also recorded in a journal in the prescribed form.

comments powered by HyperComments

Share news:

The entry was published on October 26, 2018 by admin in the Electrical Safety section.

Electrical safety approval

An electrical safety permit is the ability to independently work with electrical installations (maintenance, repair, inspection, testing). Depending on the access group, a specialist has the right to perform one or another amount of work. Electrical safety groups are assigned sequentially. The timing of electrical safety certification depends on the training profile. The specialist first undergoes training in the “Electrical Safety” course for 72 hours and is certified for Group 2 electrical safety clearance, then, depending on work experience and education, after 3-6 months it is possible to pass an extraordinary knowledge test, receiving Group 3, and so on. .

Electrical safety approval groups:

– First (I) – for non-electrical personnel whose work poses a risk of electric shock; – Second (II) – Certification for the second group of electrical safety is carried out for electricians, workers, electricians working with power tools (voltage up to 1000V) under control; – Third (III) – for workers and management personnel who have the right to independently work with voltages up to 1000V; – Fourth (IV) – for engineers and experienced workers performing maintenance on electrical installations with voltages over 1000V; – Fifth (V) – for power engineers, electrical engineers with voltages over 1000V. Personnel are entitled to training and inspection of equipment.