GENERAL OCCUPATIONAL SAFETY REQUIREMENTS

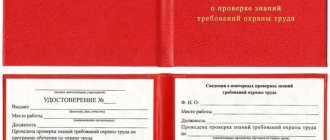

1.1. Persons at least 18 years of age who have passed: - a preliminary medical examination and have no contraindications to performing this type of work are allowed to work on a top; — introductory and initial workplace safety briefings; — fire safety briefing; — training in electrical safety with assignment of qualification group I; — on-the-job training; — training and testing of knowledge of labor protection requirements, fire safety, as well as practical skills for safe work. 1.2. At least once every 6 months, employees must undergo repeated training, at least once every 12 months - another test of knowledge of labor protection requirements, periodic medical examination - in accordance with Order of the Ministry of Health and Social Development No. 302n. 1.3. Employees are required to comply with labor and production discipline and internal labor regulations. 1.4. It is prohibited to be at the workplace in a state of alcoholic intoxication or in a state caused by the use of narcotic drugs, psychotropic or toxic substances, as well as drinking alcoholic beverages, using narcotic drugs, psychotropic or toxic substances on the territory of the enterprise, at the workplace or during working hours. 1.5. Workers performing work on the top must be provided with special clothing, shoes and other personal protective equipment in accordance with the Standards. 1.6. During work, an employee may be exposed to the following dangerous and harmful production factors: - increased voltage in an electrical circuit, the closure of which can occur through the human body; — insufficient illumination of the working area; — moving mechanisms and their parts. 1.7. Enterprise employees are required to know the escape routes in case of fire, the location of primary fire extinguishing equipment in the workplace and be able to use them. The use of fire equipment for other purposes is prohibited. 1.8. It is prohibited to independently eliminate any malfunctions that arose during the operation of the top. In case of any malfunction, you should stop the machine and inform the site foreman or shift supervisor about it. Resuming work is allowed only after completion of repair work with the permission of the site foreman. Maintenance and repair of the top should only be carried out by qualified technical personnel. 1.9. It is prohibited to work on a top that is faulty or with protective devices removed, as well as with faulty control devices or with a broken grounding circuit. 1.10. Employees of the organization are required to be able to provide first aid to victims of accidents. 1.11. Workers performing work on a top are required to: - perform only the work for which they are trained and instructed in labor safety, and authorized to perform it by the immediate supervisor of the work; - use proper hand tools and equipment; — work in overalls and safety shoes, as well as using personal protective equipment (PPE); — know and follow the rules of personal hygiene and industrial sanitation; - keep your skin, clothes, shoes, personal protective equipment clean, cut your nails short, and do not coat them with varnish; - it is prohibited to work in jewelry and watches; — keep production equipment, closets for clothes and shoes clean; - rest, eat and smoke during prescribed breaks in specially designated and equipped places; — before eating and after visiting the toilet, wash your hands with soap and water; - if you feel unwell or have skin lesions in the form of wounds, burns, pustules, peeling, go to the medical center; — workers performing work on a grinding machine are obliged to immediately notify their immediate supervisor or his/her substitute about any situation that threatens the life and health of people, about every accident that occurs at work or about a deterioration in their health. 1.12. For failure to comply with the labor protection requirements set out in these instructions, employees are liable in accordance with the current legislation of the Russian Federation.

What it is

Before talking about the development of labor protection instructions as regulatory documents, you should understand what they are.

Labor safety instructions are a document that provides a number of rules and requirements when performing a specific type of work. Also during the period of being at construction, production, and other places where professional duties are performed.

There are two types of such instructions:

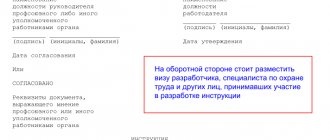

- Typical. It is intended to establish general requirements that are formed into a single act issued by the executive authority based on consultations with trade union organizations.

- Industry. This type of instructions provides rules for a specific profession or position, taking into account the characteristics of production.

The standards are based on federal laws and regulations, current GOSTs and other official information about a particular type of activity.

OCCUPATIONAL SAFETY REQUIREMENTS BEFORE STARTING WORK

2.1. Wear protective clothing, safety shoes and personal protective equipment (PPE). Fasten the clothes with all the buttons (tie the ties), avoiding hanging ends of the clothes. It is prohibited to pin clothes with pins or needles, or to keep sharp, breakable objects in clothing pockets. Do not use slippery shoes. Hair must be completely tucked under the headdress. 2.2. Obtain the necessary information from the employee handing over the shift about the condition of equipment, inventory, malfunctions that require immediate action, and orders for the upcoming shift. 2.3. Ensure good lighting of the work area. 2.4. Clear passages of foreign objects (raw materials, wheelbarrows, boxes, etc.). 2.5. Check the serviceability of working equipment and inventory. 2.6. Check that the workplace is equipped with the necessary equipment, tools, fixtures and tools for work. 2.7. Check whether the top is assembled correctly, the presence and condition of the protective casing and grounding. 2.8. Check the operation of the protective devices. Working with faulty safety devices or in their absence is strictly prohibited. 2.9. Check the serviceability of the locks. 2.10. Start the grinder at idle speed and make sure there is no extraneous noise, vibration, abnormal jamming or heating, as well as that the control and signaling devices are working. 2.11. Conveniently and sustainably place stocks of raw materials, semi-finished products, tools and accessories in accordance with the frequency of use and consumption. 2.12. Report all detected malfunctions of equipment, inventory, electrical wiring and other problems to your immediate supervisor. It is allowed to start work only after they have been eliminated.

OCCUPATIONAL SAFETY REQUIREMENTS DURING WORK

3.1. Perform only the work for which you have received training, instructions on labor protection and for which you have been authorized by the employee responsible for the safe performance of work. 3.2. It is prohibited to entrust your work to untrained and unauthorized persons. 3.3. While moving around the workshop, it is prohibited to step on electrical cables or cords of electrical equipment. 3.4. It is forbidden to work on a top that has any malfunctions. 3.5. It is forbidden to leave a working top unattended. 3.6. Use proper equipment, tools, devices, as well as special clothing, special shoes and other personal protective equipment necessary for safe work; use them only for the work for which they are intended. 3.7. Follow the rules of movement in the premises and on the territory of the organization, use only designated passages. 3.8. Keep the workplace clean and clean it in a timely manner. 3.9. When cleaning your workplace, it is prohibited to remove garbage and waste directly with your hands. Brushes, dustpans and other equipment should be used for this purpose. 3.10. It is prohibited to clutter the workplace, passages and passages to it, passages between tables, racks, to control panels, switches, evacuation routes and other passages with empty containers, equipment, or excess supplies of raw materials. 3.11. Turning the equipment on and off should only be done with dry hands. 3.12. To prevent cases of electrical injury, it is prohibited to connect a top with damaged insulation of the power cord or plug body to the electrical network. 3.13. It is prohibited to pull the plug from the electrical outlet by the cord; force must be applied to the body of the plug. 3.14. Safety and protective devices must not be modified, removed or bypassed. 3.15. It is prohibited to work on a top with faulty grounding or with damaged safety and protective devices. 3.16. All doors and tops of the grinder must be properly closed during operation. They may only be opened by authorized and properly trained technical personnel for the purpose of maintenance and repair. 3.17. Use the top only for its intended purpose. 3.18. To ensure safety, workers must be aware of and comply with relevant signs and pictograms that warn of possible hazards. 3.19. Before starting the top, you must make sure that there are no foreign objects in it and that all parts are correctly installed and securely fastened. 3.20. During operation, it is strictly forbidden to touch the moving and rotating parts of the top. Clothing and tools must be kept at a safe distance from it. 3.21. When working on a top, it is prohibited to touch the switches with wet hands or turn the equipment on and off. 3.22. When working with a loading device, you should check the operation of the cart locking system each time before starting work. 3.23. While the loading device is operating, do not stand near the transport cart (in the danger zone) or stand under it. 3.24. It is forbidden to lower limbs and other parts of the body (arms, legs, head, etc.) inside the top. 3.25. It is prohibited to use footrests, scaffolds or other aids without appropriate protective devices to enable you to reach sources of danger while the grinder is running. 3.26. The folded-up step must not be used to climb onto a running machine. 3.27. It is prohibited to stand on individual parts of the grinder and use them for cleaning. 3.28. All maintenance and cleaning operations must be carried out only with the machine switched off and de-energized. 3.29. Do not use gasoline, solvents or other flammable liquids as cleaning agents. 3.30. Do not use compressed air to clean the mince mixer. 3.31. If electric current is felt on the equipment body, working on such equipment is prohibited. It must be stopped immediately, an electrical engineer and the chief engineer of the workshop must be called to take prompt action. 3.32. In the event that noise or the grinding of foreign objects is heard in the top, work on this equipment must be stopped immediately, the mechanical repair service workers and the chief engineer must be called to take prompt action.

Storage

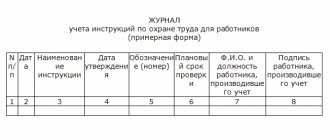

For use in work, labor safety instructions are copied in the required number of copies so that they are located:

- from a specialist who carries out labor activities in the organization;

- from the heads of structural divisions;

- from a specialist responsible for labor protection.

It is allowed to place the instructions in accessible places at the employees’ workplace or post them on appropriate stands.

When making changes or replacing a document that has lost its validity, it is sent to the archive for storage. Its shelf life is 5 years, after which it can be destroyed according to an act.

OCCUPATIONAL SAFETY REQUIREMENTS IN EMERGENCIES

4.1. In the event of any emergency (power failure, mechanical failure, excessive heating of the engine, etc.), it is necessary to turn off the equipment, post a sign warning about the equipment malfunction, inform your immediate supervisor, and call repair workers. It is prohibited to start working on faulty equipment until the faults are completely eliminated. 4.2. After an emergency stop and when restarting, the grinder must be freed from the product. Cleaning should only be done with a special tool. 4.3. In the event of an accident at work, it is necessary to provide first aid to the victim, if necessary, call an ambulance by calling 103, notify management, and, if possible, maintain the situation until the causes are investigated. 4.4. If a fire occurs, immediately stop the top, disconnect it from the power supply, notify the fire department by calling 101, notify management and begin extinguishing the fire using primary fire extinguishing agents.

OCCUPATIONAL SAFETY REQUIREMENTS AFTER WORK COMPLETION

5.1. After finishing work on the top, turn off the electric drive and hang a warning poster on the starting device: “Do not turn on! People are working!” and begin sanitary and hygienic cleaning of equipment and workplace. 5.2. It is prohibited to remove debris, product residues, and waste directly with your hands. Brushes, dustpans and other devices should be used for these purposes. 5.3. Take off overalls, safety shoes and personal protective equipment, and hand over your clothes for washing. 5.4. Wash your hands and face with warm water and soap, and take a shower if necessary. 5.5. Report all comments and malfunctions identified during the shift, as well as the measures taken, to your immediate supervisor.

We thank Ekaterina for providing the instructions! =)

Why do you need to follow safety precautions in the workplace?

The answer is obvious: “So as not to get injured.” But there are other reasons.

So, 5 reasons why you need to observe safety precautions in the workplace:

1. So that the employee remains alive, healthy and does not become disabled. Think about it, about 2,000 people die a year at Russian enterprises and about 4,000 people become disabled per year!

2. Causing damage to the health of other employees. For causing harm to the health of citizens, both administrative liability is provided (Article 5.27 of the Administrative Code) and criminal liability (Article 143 of the Criminal Code of the Russian Federation).

3. Failure to provide various benefits and guarantees not provided for by the collective agreement. Thus, many enterprises do not pay the 13th salary to violators of labor discipline.

4. Decrease in the quality of products and services.

5. Dismissal at the initiative of the employer. The administration of the enterprise has every right to terminate an employment contract for repeated violations of safety regulations or for a single gross violation of safety regulations (Articles 81 and 192 of the Labor Code of the Russian Federation).

https://youtu.be/Eo739JvBhds