Application of the OS-15 act

Depending on what forms the company decides to use (unified or independently developed), it is worth either determining the procedure for filling out independently developed forms, or using the filling instructions approved by Goskomstat. If a company decides to use a unified form, it is necessary to understand some of the features of filling out the act in form OS-15. We will provide a form and a sample of filling out the act at the end of the article.

If the installation of purchased equipment is carried out on its own, then the act is filled out at the time of the actual transfer of the equipment for installation. The act must be completed in two copies. If the installation is carried out by a third-party company under a contract method, the acceptance committee includes a representative of the contract installation organization. There is no need to draw up a separate OS-15 act for transferring equipment for safekeeping: when receiving equipment for storage, an authorized representative of the installation organization signs directly on the act, and a copy of the act is given to him.

Equipment for the production of toilet paper. How toilet paper is made

The minimum set for the production of toilet paper is as follows:

Cutting machine cutting rolls from rollers

- Band saw for cutting logs of toilet paper into rolls, JQ-D (Manufacturer-HAC);

- VC-90 Automatic planetary saw for cutting toilet paper rolls (Manufacturer: HAC);

- Equipment for cutting toilet paper from waste paper RTB 1000;

- Cutting machine (band saw) PL-41/PL-45 (Manufacturer NIKA, Russia)

https://youtu.be/6t2-NMC_otU

Rewinding and winding machine designed for rewinding raw materials

- Unwinding machine for the production of toilet paper BRS-18/2000 (Manufacturer OBS LLC);

- Unwinding machine for processing toilet paper (Manufacturer Dazen);

- Paper unwinding machine (Manufacturer: Omsk Paper Plant);

- Rewinding machine RNS 2100;

- Machine for rewinding toilet paper into rolls MNB-2E;

- Equipment for rewinding toilet paper from waste paper PTB 1000;

- Rewinding and winding machines PM-1, PM-2, PM-3, PM-4, PM-4A, PM-5/PM-5A, PM-6 (Manufacturer NIKA, Russia);

Bushing machine - for the production of cardboard bushings

- VC-180J Equipment for the production of cardboard sleeves (Manufacturer -HAC);

- Universal bushing machine – VT 42 and VT 45 (Manufacturer NIKA, Russia);

Pasting machine (in case of sticking the manufacturer’s logo on the finished product)

- Wrapping machine OS-15 (Manufacturer NIKA, Russia);

Packing machine

- Packaging machine US-5T (Manufacturer NIKA, Russia).

Examples of workshop equipment:

- VC-2200 equipment for the production of toilet paper from finished raw materials (Manufacturer -HAC);

- VC-1350 equipment for the production of toilet paper (Manufacturer -HAC);

- Equipment for the production of toilet paper SPM 2100 (Manufacturer: Thai Shuen enterprise CO).

The productivity of a toilet paper production workshop depends on the calculated productivity of the machines, the speed of winding and filling of paper, as well as the human factor. The estimated cost of such a workshop is about 4-5 thousand USD

Automated lines

The lines are designed for perforating, embossing and cutting raw materials in accordance with specified sizes. Such lines, depending on the modification, can process rolls with a width of 1200, 1750, 1950, 2150, 2350, 2550 and 2750 mm. For example,

- Toilet paper production line, PM-1150/1.8 (Manufacturer OBS LLC);

- Toilet paper production line (Manufacturer solaris);

- Automatic line for the production of toilet paper, 24 ();

The line includes: Rewinding and winding machine ARNS-24; Bushing machine VT-42; Cutting machine PL-41; Universal Packaging Machine US-5T; Pasting machine OS-15.

- Automatic cutting line for toilet paper and paper towels DM (Manufacturer Turkey);

The cost of such a line is determined by its capacity and amounts to 30-50 thousand USD.

In addition to conventional lines, there are lines designed for the production of paper from straw.

Tension control systems

Tension control systems play an important role in the production process, since maintaining a constant tension is necessary for high-quality roll formation. There are two types of such control systems: open and closed. The choice should be made based on production needs and technical characteristics of the equipment. The leading companies in tension control systems are Whichita (UK) and WarnerElectric (USA, France).

Auxiliary elements

An important role in the production process of toilet paper is given to the quality of the following elements:

- band knives of various types;

- circular knives (for rotary cutting machines);

- pulse packer;

- rotomat;

- automatic toilet paper log storage device;

- automatic machine for the production of sleeves (cardboard sleeves), etc.

https://youtu.be/HRqrw5zLhYQ

Raw materials

The raw material for the production of toilet paper is tissue paper (SGB), which is produced in 1-2 meter rolls weighing from 100 to 600 kg. Its quality is guaranteed by the relevant GOST standards. From a business point of view, it is more effective not to purchase ready-made SGB, but to produce it independently.

Waste paper, straw and cellulose can also be used as raw materials. For their processing, so-called mills are used. For example, a mill for processing cellulose with double millstones (Manufacturer Dazheng) worth 6,000 USD.

The following grades of waste paper are used for the production of toilet paper: MS-1; MS-2; MS-3; MS-7 and MS-10. If you plan to process waste paper, then the paper manufacturer should acquire special equipment, namely a paper-making machine. For example,

- Paper Making Machine (Manufacturer: DaZeng);

- Paper making equipment ke-hua;

- Paper-making machine, PM-1092 (Manufacturer Omsk Paper Plant);

- Mini plant for the production of toilet paper from waste paper 757.1092 (Manufacturer China);

- Mini-plant for processing waste paper into toilet paper PM (Manufacturer: Omsk Paper Plant).

https://youtu.be/8j10a4cuDX8

Act OS-15 (filling sample)

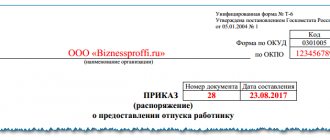

The form for the certificate of transfer of equipment for installation is filled out on both sides of the sheet. In the header of the document, general information is filled in, namely: name of the customer organization, structural unit, OKUD and OKPO form, basis for drawing up the document (name), its number and date of completion. Next, fill in the invoice, sub-account, analytical accounting code, date of delivery of the purchased equipment for installation, date of commissioning of the equipment - the actual date and the date determined by the contract. The document number and date of completion are indicated.

The main part contains general information about the acceptance and transfer of equipment for installation:

- Place of filling out the act, code according to OKPO;

- Name of the manufacturer, OKPO code;

- Name of the supplier company, OKPO code;

- Name of the company performing the installation, OKPO code.

The following contains detailed information about where the equipment was transferred for installation - the exact name of the building and the company's workshop. Information about the transferred equipment is presented in detail in a table consisting of eleven columns:

- Name of the equipment that was transferred for installation;

- Serial number assigned to the purchased equipment;

- Passport or marking number;

- Position number according to the technological diagram;

- Type, brand of equipment purchased;

- The date when the equipment arrived at the customer’s warehouse;

- Acceptance certificate number;

- Number of units of received equipment;

- Cost of one piece of equipment;

- The final (total) cost of the equipment that was purchased;

- Notes.

The reverse side of the OS-15 form contains detailed information about what was discovered during the installation of the equipment. In particular, it is necessary to record whether the equipment corresponds to the design specification or drawing. If the equipment does not comply with the declared parameters, then indicate the discrepancy. Note whether the equipment was received with technical documentation, describe in detail the composition of the kit in which the equipment was received.

Form OS-15 also includes information about equipment defects: if any were discovered, they must be listed. The detailed content and description of defects should be recorded in a separate act on identified defects (form OS-16).

In conclusion, the certificate of transfer of equipment for installation OS-15 contains information about the suitability of the equipment for installation. The act is signed by a representative of the customer company, which handed over the equipment for installation, and a representative of the company carrying out the installation, indicating the position held and a transcript of the signature. Also, the OS-15 act (a sample of the filling below) is signed by the financially responsible person, indicating the position and a transcript of the signature - this confirms the fact that the equipment has been accepted for safekeeping. One copy of the act must be given to the financially responsible person. The date the document was completed is indicated.

Below you can download the unified form of the OS-15 act and see an example of how to fill it out.

Form OS-15 (filling sample)

Sample of an act of acceptance and transfer of equipment for installation

The act has two sides.

- On the front page, the name of the customer company is first entered, indicating the OKPO code, as well as the structural unit that accepted the equipment for installation.

- Then the basis for the formation of this document is indicated (here is a link to the agreement with its number and date of preparation).

- Below is the number of the act itself and the date it was written. On the left is the analytical accounting code and the date: the object was handed over for installation and commissioning (as it should be according to the contract and as it actually happened).

- Next, the place of drawing up the act is indicated (not just a locality, as in most documents, but the full address of the enterprise), then the names of the manufacturer, supplier and installation organization are entered (opposite all these lines in the table on the left you need to put their OKPO codes).

- After this, the structural department (workshop, site) that accepted the object for installation is indicated.

Below is a table in which you should enter detailed information about the equipment:

- its name,

- numbers (factory and passport),

- position according to the technological scheme,

- type or brand,

- date of receipt of the item at the customer’s warehouse,

- acceptance certificate number,

- quantity and cost in rubles per unit and “total”.

If there is any additional information, it must be indicated in the last column of the table.

On the back of the form you should fill out:

- whether the received equipment corresponds to the drawing or design documentation,

- its completeness,

- identified malfunctions, marriages and defects,

- a note on the suitability of this equipment for further use.

After this, the document is endorsed by representatives of the customer company, the installation organization and the financially responsible person who accepts the equipment for storage.

After signing the act, responsibility for the quality and safety of the equipment passes to the installation contractor.

It is not necessary to certify the act with seals, because Now legal entities have every right not to use stamped products in their activities (unless otherwise stated in their local regulatory documents).

How to fill out the tabular part of a document

The columns of the tabular part of the act are filled in as follows:

- 1 – name of special equipment;

- 2 – serial number of the object;

- 3 – equipment passport number;

- 4 – equipment position number according to the technological diagram;

- 5 – type and brand of object;

- 6-7 – date and number of the act on the basis of which the equipment was received at the warehouse;

- 8 – number of objects in pieces;

- 9 – price of one object;

- 10 – total cost of all equipment;

- 11 – column for notes.

Reflection of transactions in accounting

The contractor's costs for the purchase of equipment requiring installation, the cost of which is included in the estimate, are recognized as part of material costs (subclause 4, clause 1, article 254 of the Tax Code of the Russian Federation).

Note that in the contractor’s accounting, equipment purchased for the purpose of performing installation work cannot be attributed to accounts 01 “Fixed assets” and 07 “Equipment for installation,” since the contractor is not the owner of this equipment. He accounts for equipment in account 10 “Materials” (sub-account “Purchased semi-finished products and components, structures and parts”) at the actual cost, that is, at the amount of costs for its purchase without VAT. Such rules are provided for in paragraphs 2, 5, 6 of PBU 5/01, approved by order of the Ministry of Finance of Russia dated June 9, 2001 No. 44n.

DEBIT 20 CREDIT 10 – the cost of installed equipment is written off.

These expenses are written off to the debit of account 90 “Sales” (sub-account “Cost of sales”) on the date of recognition of revenue from the work. This follows from paragraphs 5, 9, 19 of PBU 10/99, approved by order of the Ministry of Finance of Russia dated May 6, 1999 No. 33n.

The contractor can also account for purchased equipment on account 41 “Goods”. When recognizing revenue in accounting, the cost of goods is written off from account 41 to the debit of account 90.