Main regulatory document

The fundamental order on labor protection during the operation of electrical installations No. 328n was adopted by the Ministry of Labor on July 24, 2013. Please note that since the end of 2020, a lot of changes and additions have been made to it (Order of the Ministry of Labor dated February 19, 2016 No. 74n).

It installs:

- Mandatory labor protection rules when working with various electrical installations.

- Electrical safety groups for relevant employees and criteria for their assignment (Appendix No. 1).

- Mandatory forms of documents on labor protection in this area (Appendices No. 2 – 8).

These are the following forms:

- certificate of testing knowledge of working rules in electrical installations;

- a certificate of testing knowledge of the rules by employees who control electrical installations;

- protocol for testing knowledge of operating rules in electrical installations;

- logbook for testing knowledge of operating rules in electrical installations (for electric power organizations);

- logbook for testing knowledge of working rules in electrical installations for other organizations;

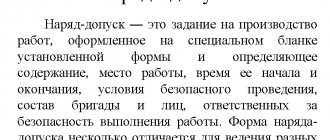

- work permit for work in electrical installations (+ rules for filling it out);

- log of work according to work permits and orders for work in electrical installations.

The employer is responsible for labor protection.

He can, by his administrative document, transfer the supervision of this issue to another manager with administrative functions - the chief engineer, vice president, technical director, deputy director, as well as the head of a branch or representative office. Also see "New rules for working at height and occupational safety."

X.

Labor protection during the preparation of the workplace and the initial admission of the team to work in electrical installations according to the work permit and order

10.1. It is not allowed to change the measures for preparing workplaces provided for in the work order, namely: technical measures taken before the start of work to prevent exposure of workers to hazardous and harmful production factors in the workplace.

If doubt arises about the sufficiency and correctness of measures to prepare the workplace and the possibility of performing the work safely, the preparation of workplaces should be stopped, and the planned work should be postponed until a new work order is issued, which provides for technical measures that eliminate the doubts about safety.

10.2. In cases where the work foreman combines the duties of a permitter, he must prepare the workplace with one of the team members who has group III.

10.3. Before being allowed to work, the applicant must ensure that technical measures to prepare the workplace are completed through personal inspection, according to entries in the operational log, according to the operational scheme and according to reports from the operational, operational and repair personnel of the organizations involved in the work.

10.4. The responsible manager and the work performer (supervisor), before admitting him to work, must find out from the person allowing him what measures have been taken to prepare the workplace for work, and together with the person admitting him, check this preparation through personal inspection within the workplace.

In the absence of operational personnel, but with their permission, the responsible work manager, together with the work manufacturer, can independently check the preparation of the workplace for work.

10.5. Admission to work according to work orders and instructions must be carried out directly at the workplace.

Admission to work by order in cases where preparation of the workplace is not necessary is not required at the workplace, and on overhead lines, overhead lines and cable lines is not required.

10.6. Admission to work is carried out after checking the preparation of the workplace. In this case, the person admitting must check the compliance of the brigade composition with the composition specified in the order or order, according to the personal identification cards of the brigade members; prove to the team that there is no voltage by demonstrating the installed groundings or checking the absence of voltage if the groundings are not visible from the workplace, and in electrical installations with a voltage of 35 kV and below (where the design allows) - by subsequently touching live parts with your hand.

10.7. The start of work according to an order or order must be preceded by targeted instruction, providing instructions for the safe performance of specific work in an electrical installation, covering the category of workers identified by the order or order, in a sequential chain from the employee who issued the order, who gave the order, to the team member or performer.

Without targeted instruction, permission to work is not permitted.

Targeted instruction during work on the job is carried out by:

the employee issuing the work order - to the responsible work manager or, if a responsible manager is not appointed, to the work supervisor (supervisor);

admitting - to the responsible work manager, work foreman (supervisor) and team members;

responsible work manager - the work foreman (supervisor) and team members;

the work foreman (supervisor) - to the team members.

Targeted instruction during work according to the order is carried out by:

an employee who gives an order to the manufacturer (supervisor) or the direct performer of the work;

allowing - to the work foreman (supervisor), team members (performers).

the work foreman - to the team members.

It is allowed to carry out targeted briefing by the employee issuing the order, giving the order over the phone.

When a new team member is introduced into the team, the briefing, as a rule, should be carried out by the work supervisor (supervisor).

10.8. The employee issuing the order, giving the order, the responsible work manager, the work performer, in the targeted briefings they carry out, in addition to electrical safety issues, must give clear instructions on the technology for safe work, the use of lifting machines and mechanisms, tools and devices.

The supervisor instructs team members on measures for safe work, excluding the possibility of electric shock, and on the procedure for moving team members around the territory of the electrical installation. The work foreman instructs the team on safe technology for performing work, the use of tools and devices.

In the targeted briefing, the work manager is obliged to give the team members comprehensive instructions in order to prevent electric shock.

10.9. In the targeted briefing, the person permitting must familiarize the team members with the contents of the work order, instructions, indicate the boundaries of the workplace, the presence of induced voltage, show the equipment closest to the workplace and the live parts of the equipment being repaired and adjacent connections, which are not allowed to be approached, regardless of whether they are under voltage or not.

10.10. When working as part of a work order, targeted instructions must be signed by the employees who conducted and received the instructions in the tables of the work order, the form of which is provided for in Appendix No. 7 to the Rules.

When working under orders, targeted briefings must be signed by the employees who conducted and received the briefing in the work log for work orders and orders, the form of which is provided for in Appendix No. 8 to the Rules.

10.11. Permission to work is issued in two copies of the work order, one of which remains with the work producer (supervisor), and the second with the employee who allows them.

When the work performer combines the responsibilities of the permitter, the permit is issued in one copy of the work order.

Admission to work according to work orders and orders is formalized in the work log according to work permits and orders, the form of which is provided for in Appendix No. 8 to the Rules, with a record of permission to work in the operational journal.

XI. Team supervision.

Changes in brigade composition during

carrying out work in electrical installations

11.1. After admission to work, supervision of the team’s compliance with safety requirements is assigned to the work manager (responsible manager, supervisor), who must organize his work in such a way as to monitor all members of the team, being, if possible, in the area of the workplace where the most dangerous work is performed .

It is not allowed to combine supervision by an observer with the performance of any work.

11.2. The work foreman (supervisor), in the event of a temporary departure from the workplace and the inability to shift the performance of his duties to the responsible work manager, permitting or employee who has the right to issue work orders, is obliged to remove the team from the place of work (take the team out of the control room, close the entrance doors to lock, organize the descent of team members from the overhead line supports).

During his temporary absence from the workplace, the work manager (supervisor) must transfer the work order to the employee who replaced him.

It is not allowed for one worker (supervisor) or members of a team without a worker (supervisor) to remain in electrical installations with voltages above 1000 V. The following types of work may be exceptions:

adjustment of switches, disconnectors, the drives of which are located in another room;

installation, testing of secondary circuits, protection devices, electrical automation, alarms, measurements, communications;

laying power and control cables;

testing of electrical equipment with high voltage supply, when it is necessary to monitor the equipment being tested and warn about the danger of unauthorized persons approaching it.

The specified work is carried out along the way on the basis and conditions provided for in paragraphs 6.12 and 6.13 of the Rules.

11.3. It is allowed, with the permission of the work supervisor (supervisor), to temporarily leave the workplace of one or more team members. At the same time, there is no need to remove them from the brigade. In electrical installations with voltages above 1000 V, the number of team members remaining at the workplace must be at least two, including the work supervisor (supervisor).

Team members with group III can independently leave the switchgear and return to the workplace, team members with group II can only be accompanied by a team member with group III, or an employee who has the right to individually inspect electrical installations. It is not allowed to leave the door unlocked after leaving the control room.

Returning team members can begin work only with the permission of the work manager (supervisor).

Team members who do not have the right to independently work in electrical installations may leave the switchgear and return to the workplace only accompanied by an employee who has the right to individually inspect electrical installations, or an observer, if he can be replaced under the conditions provided for in paragraph 11.2 of the Rules.

11.4. If violations of the Rules are detected or other circumstances are identified that threaten the safety of workers, team members must be removed from the workplace and the work order must be confiscated from the work manager (supervisor). Only after the detected violations have been eliminated, the team is allowed to work again with a new work order.

11.5. The employee who issued the order or another employee who has the right to issue the order in a given electrical installation is allowed to change the composition of the team. Instructions about changes in the composition of the team are allowed to be transmitted by telephone, radio or by hand to the permitting, responsible manager or work foreman (supervisor), who in the work order certifies with his signature the changes made to the work order and the surname and initials of the employee who gave the instruction for the change.

When changing the composition of the brigade, the requirements of paragraph 5.15 of the Rules must be observed. The work foreman (supervisor) is obliged to instruct the workers included in the team.

11.6. If the responsible manager or work supervisor (supervisor) is replaced, the composition of the team changes by more than half, or the working conditions change, the work order must be reissued.

XII. Transfer to another workplace

12.1. In switchgear with voltages above 1000 V, the transfer of the team to another workplace is carried out by the permitter. This translation can also be carried out by the responsible manager or the work supervisor (supervisor) in accordance with the instructions of the employee issuing the order, with an entry in the “Separate instructions” line of the order, as well as taking into account the requirements provided for in paragraphs 6.10, 6.12 of the Rules.

12.2. Transfer to another workplace is indicated in the work order. A transfer carried out by an admitting member of the operational staff is drawn up in two copies of the work order, except for the cases provided for in paragraph 6.1 of the Rules.

12.3. In switchgear with voltage up to 1000 V, as well as on one overhead line, overhead line, cable line, transfer to another workplace is carried out by the work supervisor (supervisor) without registration in the work order.

12.4. When performing work without shutting down the equipment, only the transfer of the team from one plant to another is subject to registration in the work order.

XIII. Registration of work breaks

and re-entry to work in electrical installations

13.1. When there is a break in work during the working day (for lunch, according to working conditions), the team must be removed from the workplace, and the doors of the control room must be locked.

The work order remains with the work producer (supervisor). Team members do not have the right to return to the workplace after a break without a work supervisor (supervisor). Admission to work after such a break is carried out by the work foreman (supervisor) without indication in the work order.

13.2. When there is a break in work due to the end of the working day, the team must be removed from the workplace.

Safety posters, fences, flags, groundings are not removed.

The work performer (supervisor) must hand over the work order to the permitter, and if the permitter is not present at the workplace, leave the work order in the designated place. In electrical installations that do not have local operational personnel, the work manager (supervisor) is allowed to keep the work crew at the end of the working day.

The completion of the work is signed by the work foreman (supervisor) in his copy of the work order.

13.3. Repeated admission to work in subsequent days at the prepared workplace is carried out by the person admitting him or with his permission by the responsible work manager. Permission for re-admission is recorded in the operational log. In this case, permission to work from higher operational personnel is not required.

The work foreman (supervisor), with the permission of the permitter, has the right to allow the team to work at the prepared workplace, if he is assigned to do so, with an entry in the “Separate instructions” line of the work order.

When resuming work the next day, the work manager (supervisor) must ensure the integrity and safety of the abandoned posters, fences, flags, as well as the reliability of grounding and allow the team to work.

Permission to work, carried out by an admitting member of the operational staff, is issued in two copies of the work order; permission to work, carried out by the responsible manager or the work producer (supervisor), is documented in a copy of the work order kept by the work producer (supervisor).

XIV. Handover and acceptance of the workplace, closing of the work permit, instructions after completion of work in electrical installations

14.1. After complete completion of the work, the work foreman (supervisor) must remove the team from the workplace, remove the temporary fences, portable safety posters, flags and grounding installed by the team, close the doors of the electrical installation with a lock and document the complete completion of the work with his signature. After checking the work sites, the responsible work manager must formalize the complete completion of the work in the work order.

14.2. The work performer (supervisor) must inform the operational personnel on duty or the employee who issued the work order about the complete completion of the work and his fulfillment of the requirements of paragraph 14.1 of the Rules.

14.3. After the complete completion of the work, the work contractor (supervisor) must hand over the work order to the permitter, and in his absence, leave it in a designated place, for example, in the folder of existing work orders. If handing over the work order after complete completion of the work is difficult, then with the permission of the permitter or an employee from among the operational personnel, the work performer (supervisor) has the right to keep the work order. In this case, as well as when the work performer combines the duties of the permitter, he must, no later than the next day, hand over the work order to the operational personnel or the employee who issued the work order, and in remote areas - to the administrative and technical staff of the site.

14.4. After receiving the work order documenting the complete completion of the work, the permitter must inspect the workplaces and inform the employee issuing permission to prepare workplaces and permission to work, as well as the operational personnel in whose operational control the electrical installation is located, about the complete completion of the work and the possibility turning on the electrical installation.

14.5. The completion of work according to an order or order after inspecting the place of work must be reflected in the work log for orders and orders and the operational journal.

XV. Labor protection when turning on electrical installations after complete

completion of work

15.1. An employee from among the operating personnel who has received permission (order, command) to turn on an electrical installation after complete completion of work in it must, before turning it on, make sure that the electrical installation is ready to turn on (check the cleanliness of the workplace, the absence of tools), remove temporary fences, portable safety posters and groundings installed during preparation of the workplace by operational personnel, restore permanent fences.

15.2. The person admitted from among the operational and repair personnel is allowed to be given the right, after completing work in the electrical installation, to turn it on without obtaining additional permission or order.

Granting the right to such inclusion must be recorded in the “Separate instructions” line of the work order.

The right to such inclusion is granted only if other teams are not allowed to work on the electrical installation or its area.

15.3. In emergency cases, operating personnel or permitting personnel may start work on electrical equipment or electrical installations put out for repairs in the absence of the team until the work is completely completed, provided that before the work foreman arrives and the work order is returned to them, workers are stationed at the workplace and are required to notify the work foreman and all members of the team that the electrical installation is turned on and resumption of work is not allowed.

XVI. Occupational safety when performing technical measures to ensure the safety of work with stress relief

16.1. When preparing a workplace with voltage relief, in which the voltage is removed from the current-carrying parts of the electrical installation on which work will be carried out by disconnecting switching devices, disconnecting busbars, cables, wires and measures are taken to prevent the supply of voltage to the current-carrying parts to the place of work, there must be The following technical measures were carried out in the specified order:

the necessary shutdowns have been made and measures have been taken to prevent the supply of voltage to the work site due to erroneous or spontaneous switching on of switching devices;

prohibiting posters must be posted on manual drives and on remote control keys of switching devices;

checked that there is no voltage on live parts that must be grounded to protect people from electric shock;

grounding installed;

“Grounded” signposts have been posted, workplaces and live parts that remain energized have been fenced off if necessary, and warning and instructional posters have been posted.

XVII. Labor protection when performing

outages in electrical installations

17.1. When preparing the workplace, the following should be disabled:

live parts on which work will be carried out;

unfenced live parts, to which people, machinery and lifting machines may accidentally approach at a distance less than that specified in Table No. 1;

control and power supply circuits for the drives, the air in the control systems of the switching devices is closed, the springs and weights at the drives of the switches and disconnectors are removed.

17.2. In electrical installations with voltages above 1000 V, there must be a visible gap on each side from which switching on the switching device does not exclude the supply of voltage to the workplace. A visible break may be created by disconnecting disconnectors, removing fuses, disconnecting separators and load switches, disconnecting or removing busbars and wires.

In the absence of a visible break, in complete factory-made switchgear with withdrawable elements, as well as in complete switchgear with gas insulation (hereinafter referred to as GIS) with a voltage of 35 kV and above, it is allowed to check the disconnected position of the switching device using a mechanical indicator of the guaranteed position of the contacts.

Power transformers and voltage transformers associated with the section of the electrical installation allocated for work must be disconnected and their circuits must also be disassembled from their other windings to eliminate the possibility of reverse transformation.

When remotely controlling switching devices from a workplace, allowing operational personnel performing operational maintenance of electrical installations to remotely (from a computer monitor) control switching devices, grounding blades of disconnectors and determine their position, use electrical connection diagrams of electrical installations displayed on a computer monitor, electrical parameters ( voltage, current, power), as well as to read incoming emergency and warning signals (hereinafter referred to as the automated workstation of operational personnel (AWP)), personnel are not allowed to be in the switchgears in which these switching devices are located.

17.3. After disconnecting switches, disconnectors (isolators) and manually operated load switches, you must visually verify that they are disconnected and that there are no bypass jumpers.

When remotely controlling switching devices with an automated workplace, the position of switching devices (switches, disconnectors, grounding knives) is checked using the automated workplace alarm. General monitoring of the condition of switching devices is carried out by means of technological video surveillance. A visual check of the actual position of the switching devices must be performed after completing the entire complex of operations directly at the installation site of the switching devices.

17.4. In electrical installations with voltages above 1000 V, to prevent erroneous or spontaneous switching on of switching devices that supply voltage to the place of work, the following measures must be taken:

For disconnectors, separators, load switches, manual drives in the off position must be locked with a key or a removable handle (hereinafter referred to as a mechanical lock). In electrical installations with a voltage of 6-10 kV with single-pole disconnectors, instead of a mechanical lock, it is allowed to put dielectric caps on the knives;

for disconnectors controlled by an operating rod, stationary fences must be locked with a mechanical lock;

For drives of switching devices that have remote control, the power circuits and control circuits must be turned off, and for pneumatic drives, in addition, on the compressed air supply pipeline, the valve must be closed and locked with a mechanical lock and compressed air must be released, while the drain valves must be left in the open position;

when remotely controlled from an automated workstation, the power circuits of the disconnector drives must be turned off, the operating mode selection key in the control cabinet is set to the “local control” position, the disconnector control cabinet is locked with a mechanical lock;

for load and spring drives, the closing weight or closing springs must be brought to the non-working position;

Prohibition posters must be posted.

Measures to prevent erroneous switching on of switchgear switching devices with withdrawable trolleys must be taken in accordance with the requirements provided for in paragraphs 29.1, 29.2 of the Rules.

17.5. In electrical installations with voltages up to 1000 V, the voltage must be removed from all live parts on which work will be carried out by disconnecting manually operated switching devices, and if there are fuses in the circuit, by removing them. If there are no fuses in the circuit, preventing the switching devices from being switched on incorrectly must be ensured by such measures as locking the handles or doors of the control cabinet, closing the buttons, and installing insulating pads between the contacts of the switching device. When removing voltage using a remote-controlled switching device, it is necessary to open the secondary circuit of the switching coil.

The listed measures can be replaced by disconnecting or disconnecting the cable or wires from the switching device or from the equipment on which work is to be carried out.

Prohibition posters must be posted.

17.6. The disconnected position of switching devices with voltages up to 1000 V with contacts inaccessible for inspection is determined by checking the absence of voltage at their terminals or at the outgoing busbars, wires or terminals of the equipment included by these switching devices. Checking the absence of voltage in complete factory-made switchgear can be done using built-in stationary voltage indicators.

XVIII. Hanging prohibition posters

18.1. On the drives (drive handles) of manually controlled switching devices (switches, separators, disconnectors, knife switches, automatic machines), in order to avoid the supply of voltage to the workplace, posters “Do not turn on! People are working."

For single-pole disconnectors, posters are hung on the drive of each pole, for disconnectors controlled by an operating rod on the fences. On the valves that block air access to the pneumatic drives of the disconnectors, a poster “Do not open! People are working."

At connections with voltages up to 1000 V that do not have switching devices, the poster “Do not turn on! People are working” must be posted near the removed fuses, in switchgear - in accordance with clause 29.2 of the Rules.

Posters must be posted on keys and buttons of remote and local control, as well as on automatic machines or at the location of removed fuses of control circuits and power supply circuits of switching device drives.

When remotely controlling switching devices with an automated workplace, similar safety posters must, in addition, be displayed next to the graphic designation of the corresponding switching device on the automated workplace diagram.

18.2. On the drives of switching devices that are switched off for work on overhead lines or cable lines, regardless of the number of working crews, one poster “Do not turn on! Work on the line." When remotely controlling switching devices with automated workstations, the prohibitory sign “Do not turn on! Work on the line! is displayed on the diagram next to the symbol of the switching device that supplies voltage to the overhead line or cable line. This poster is hung up and removed at the direction of the operating personnel who keep track of the number of crews working on the line.

XIX. Occupational safety when checking the absence of voltage

19.1. It is necessary to check the absence of voltage with a voltage indicator, the serviceability of which must be established before use using special devices intended for this purpose or by approaching live parts that are known to be energized.

In electrical installations with voltages above 1000 V, it is necessary to use dielectric gloves when using the voltage indicator.

In factory-made complete switchgears (including those filled with SF6 gas), the absence of voltage is checked using built-in stationary voltage indicators.

In electrical installations with a voltage of 35 kV and above, to check the absence of voltage, you can use an insulating rod by touching it several times to live parts. A sign of lack of tension is the absence of sparking and crackling. On single-circuit overhead lines with a voltage of 330 kV and above, a sufficient sign of the absence of voltage is the absence of corona.

When remotely controlling switching devices and grounding knives with an automated workplace, it is allowed to check the absence of voltage, which is carried out before turning on the grounding knives by checking the diagram displayed on the automated workplace monitor. For SF6 equipment - with appropriate operational interlock and permission from the manufacturer.

19.2. In the switchgear, one employee from among the operating personnel who has group IV in electrical installations with voltages above 1000 V, and who has group III in electrical installations with voltages up to 1000 V is allowed to check the absence of voltage.

On overhead lines, the absence of voltage must be checked by two workers: on overhead lines with voltages above 1000 V - workers with groups IV and III, on overhead lines with voltages up to 1000 V - workers with group III.

19.3. It is allowed to check the absence of voltage by checking the circuit in situ:

in outdoor switchgear, switchgear and complete transformer substation (hereinafter referred to as KTS) of outdoor installation, as well as on overhead lines during fog, rain, snowfall in the absence of special voltage indicators;

in outdoor switchgear with a voltage of 330 kV and higher and on double-circuit overhead lines with a voltage of 330 kV and higher.

When calibrating the circuit in situ, the absence of voltage at the inputs of overhead lines and cable lines is confirmed by the person on duty, in whose operational control the lines are located.

Verification of overhead lines in kind consists of checking the direction and external signs of the lines, as well as the designations on the supports, which must correspond to the dispatcher names of the lines.

19.4. On overhead lines, when hanging wires at different levels, check the absence of voltage with a pointer or rod and install grounding from bottom to top, starting from the bottom wire. With a horizontal suspension, the check should begin with the nearest wire.

19.5. In electrical installations with voltages up to 1000 V with a grounded neutral, when using a two-pole indicator, it is necessary to check the absence of voltage both between the phases and between each phase and the grounded equipment body or protective conductor. It is allowed to use a previously tested voltmeter. The use of control lamps is prohibited.

19.6. Devices signaling the device's off position, blocking devices, and constantly switched on voltmeters are only additional means of confirming the absence of voltage, and based on their readings one cannot make a conclusion about the absence of voltage.

contents .. 1 2 3 4 ..

For whom is it required?

The order in question on labor protection during the operation of electrical installations is mandatory for all employers. Be it an organization or an individual. The organizational and legal form also does not matter.

Mitrud's order affects not only purely electrical and electrical engineering personnel. These are other workers who are busy:

- maintenance of electrical installations;

- carry out operational switching in them;

- organize and carry out construction, installation, adjustment, repair work, testing and measurements;

- control the technological operating modes of electric power facilities and energy receiving installations of consumers.

An employer, based on the specifics of its activities, can introduce additional safety requirements that do not contradict the order of the Ministry of Labor. Occupational safety requirements must be set out in the relevant instructions and communicated to the employee in the form of orders, instructions, and briefings.

Labor protection requirements before starting work

Before starting to perform tasks, the employee must:

- Conduct an external inspection of the place of his work and put it in proper order.

- Adjust the lighting mode, make sure that the brightness of the light is sufficient, and that there are no reflections or glare on the screen; the luminous flux coming towards it should also not hit the monitor.

- Check whether the equipment is correctly connected to the power supply.

- Use a special cloth to wipe the computer monitor and surge protector so that static electricity does not accumulate during operation.

- Check and adjust the installation of the computer chair, position the monitor at the desired angle in a given plane. There should be no tension in the body and the eyes should not get tired when performing management tasks.

If you discover any shortcomings and if you are not sure that everything during preparation was done correctly, then you must inform your manager or eliminate the shortcomings yourself, only after starting work.

On-the-job internship

Internship is required only for workers employed in harmful and dangerous working conditions. To determine whether an employee needs an internship, it is enough to read his employment contract. If the working conditions in the contract are optimal and acceptable, then an internship for this employee is not mandatory.

But there is a category of workers who, regardless of working conditions, must undergo on-the-job training (see federal norms and regulations in the field of industrial safety).

These are workers who maintain and repair technical devices. For example, a slinger’s working conditions are acceptable, but an internship is mandatory for him.

The internship is formalized by order:

“Ivanov Ivan Ivanovich will be assigned an internship under the leadership of Petrov Petrovich in the number of ________ shifts from _____ to ________”

OCCUPATIONAL SAFETY REQUIREMENTS IN EMERGENCIES

4.1. In the event of an emergency, the employee is obliged to: - immediately stop work, disconnect office equipment and other electrical equipment from the power supply network and report the occurrence of an emergency and its nature to the immediate supervisor, and in his absence, to the senior manager; if necessary, leave the danger zone; — under the leadership of the immediate supervisor, take part in eliminating the emergency situation, if this does not pose a threat to the health or life of workers; - in the event of malfunctions in the operation of office equipment or other equipment, as well as in the event of disturbances in the operation of the electrical network (burning smell, extraneous noise when operating office equipment and other equipment, or the sensation of electric current when touching their cases, flashing lamps, etc.); d.) disconnect office equipment and other equipment from the power supply, call technical personnel and inform your immediate supervisor about this; - in case of detection of malfunctions of furniture and fixtures, stop using them, call technical personnel and report this to your immediate supervisor; — in the event of a temporary interruption of power supply, disconnect office equipment and other electrical equipment from the power supply network; - do not start work until damage and malfunctions of office equipment and workplace equipment are completely eliminated or the emergency situation is eliminated; - if a fire occurs, it is necessary to stop work, call the fire brigade, disconnect office equipment and other equipment from the power supply, notify nearby people about the fire, take measures to evacuate people from the danger zone and take part in extinguishing the fire using the available primary fire extinguishing means, and if impossible extinguish the fire and leave the danger zone, acting in accordance with fire safety instructions and evacuation plans; — extinguish a fire using powder or carbon dioxide fire extinguishers with the mandatory use of personal protective equipment; - in case of accidents with other employees, provide first aid to the victim, help transport him to a health center or the nearest medical facility, and, if necessary, call medical workers to the scene of the incident; - immediately inform your immediate supervisor about an accident that happened to an employee or through his fault, as well as about any accident involving other employees of your own or a third-party organization, which was witnessed by the employee; — take measures to preserve the situation of the accident, if this does not involve a danger to the life and health of people; — when investigating an accident, the employee must report all the circumstances of the incident known to him; — in the event of terrorist acts or the threat of their commission, act in accordance with emergency safety recommendations in force in the organization; — in the event of detection of violations of labor safety requirements in the office premises that cannot be eliminated on their own, as well as in the event of a threat to the life or health of the employee or other employees, inform your immediate supervisor, suspend work and leave the danger zone.