The part of the production process that is aimed at providing it with energy, technologically equipping workplaces, as well as repairing and restoring fixed production assets is called auxiliary production. It ensures efficient and uninterrupted operation of the main production. That is why main and auxiliary production are closely interconnected. The products of the latter are consumed primarily by the workshops and services of the enterprise itself.

Problems to be solved

The main tasks that auxiliary production solves include the following:

- providing the enterprise with various types of necessary energy (gas, steam, electricity);

- repair and production of containers, special tools, technological equipment;

- repair and adjustment of mechanical and electrical equipment, transport mechanisms, as well as instrumentation;

- care of equipment, control over its use and safety;

- repair of household equipment, structures and buildings;

- reception, storage, issuance of materials, raw materials, semi-finished products, tools, equipment.

Structure of auxiliary facilities

Auxiliary production consists of the following elements:

- service facilities (warehouses, transport, etc.), services in the main workshops;

- auxiliary shops (energy, mechanical repair, tool) depending on the nature of the industries;

- regulation of loading and unloading and transport and storage operations.

Increasing labor productivity is an important factor contributing to increased efficiency of the entire production process. Workers who service auxiliary production are classified as auxiliary workers. Almost all large enterprises have a complex of areas, services and auxiliary workshops. The main and auxiliary production are comparable in size and specificity of the industry.

What applies to auxiliary production

Ancillary manufacturing facilities are subsidiary units to the main product production lines. The tasks of support departments may include:

- supply of energy resources;

- transport maintenance;

- repair and modernization of fixed assets;

- creation of tools, parts, fasteners, preparation of spare parts;

- erection of temporary structures;

- extraction of construction raw materials and materials;

- logging work;

- processing of agricultural products.

Auxiliary production is needed to ensure uninterrupted production of products and at the same time minimize costs for additional services in favor of third parties. They are formed in the form of separate workshops, departments and structural divisions, and can be represented by laboratory centers, counting stations and computing complexes.

NOTE! Auxiliary production does not include enterprise services that are part of departments or structural units (design units, chief engineer or chief power engineer).

The characteristic features of an auxiliary production unit are:

- lack of manufacturing capabilities for core product lines;

- focus on servicing the main workshops and the availability of facilities with equipment for the production of semi-finished products;

- the results of work in auxiliary departments when transferring manufactured semi-finished products to the main technological department are reflected in the calculation of the cost of goods.

Auxiliary production is divided into the following types:

- Mechanical repair workshops.

- Transport departments.

- Energy economy.

- Refrigeration equipment service departments.

- Construction of temporary structures on construction sites.

- Warehouse facilities.

BY THE WAY! With a significant increase in the share of products they produce in relation to other areas of activity, auxiliary production can become the main production divisions.

Repair shops are responsible for diagnosing equipment, repairing it, and performing regular preventive maintenance. Energy structures may include:

- boiler rooms:

- sewer communications;

- water supply system;

- electrical substations;

- transformer installations;

- diesel or gasoline generators;

- gas and electric networks;

- radio networks;

- furnace equipment;

- electrical equipment repair department.

Energy management is required for large volumes of energy consumption. The department is responsible for energy production and its supply to production workshops. Transport departments use several types of vehicles:

- external;

- in-shop;

- intershop;

- warehouse

For continuous transport services, piping systems and conveyor structures can be used.

Warehouse facilities are needed to create stocks of products and semi-finished products and ensure the safety of goods. Warehouse areas can be used for short-term and long-term placement of product groups. According to their purpose, warehouses are closed, open and semi-closed, supply, general plant, workshop, production, and sales. Depending on their functionality, warehouses are classified into universal or specialized categories.

Repair facilities

This is a set of production departments that carry out measures to monitor the condition of equipment, care for it and timely repair.

Repair auxiliary production at large enterprises may include the following divisions:

- electrical repair shop;

- mechanical repair shop;

- repair and construction shop;

- area where repairs of sanitary equipment are carried out.

The process of repairing technological equipment at the enterprise is based on the following systems:

1. PPR systems (planned preventive maintenance) - a series of planned organizational and technical measures for the care, repair and supervision of equipment, aimed at preventing its premature wear and preventing accidents. This also includes the modernization of equipment that occurs during its repair.

2. Repair systems based on the results of technical diagnostics. Any type of repair is carried out only after an objective assessment of the technological condition of the equipment.

Together, these systems help to significantly reduce the costs of auxiliary production.

Organization of auxiliary workshops and services of the enterprise

Organization of auxiliary workshops and services of the enterprise

Goals and objectives of auxiliary departments and services of enterprises. Organization of repair services of enterprises. Organization of energy services. Organization of transport facilities. Organization of warehouse facilities. Organization of logistics of the enterprise (MTS).

Production shops (sites, workshops) are divided into two groups:

1. Main production workshops , where products intended for sale are directly manufactured. They are formed in accordance with the profile of the enterprise and depending on specific types of products, scale and production technology.

The main tasks of the main workshops include : timely production of products, reduction of production costs, improvement of product quality, the possibility of timely restructuring of production in accordance with the changing needs of the market. These problems are solved on the basis of rational specialization and placement of workshops, their cooperation and ensuring proportionality of the production process from the first to the last operation.

There are the following forms of specialization of workshops:

- subject specialization (concentration in separate workshops of the main part or the entire production process for the manufacture of specific types and standard sizes of finished products); detailed (unit-by-unit) specialization (assigning to each workshop the production of individual parts or machine assemblies); technological (stage-by-stage) specialization (operational division of labor between workshops); territorial specialization (each workshop can perform the same functions in territories remote from each other).

2. Auxiliary and service workshops , the result of which is consumed within the enterprise itself.

The main task of auxiliary workshops is to ensure the normal, uninterrupted operation of the main production workshops.

Auxiliary workshops include workshops and production areas for:

- manufacturing, repair and adjustment of devices, instruments, equipment; supervision of the performance and repair of equipment, machines, mechanisms, buildings, structures; provision of electrical and thermal energy, supervision and repair of electrical equipment and heating networks; intra-production and external transportation of raw materials, materials, workpieces, finished products; enterprise warehouses.

Production program of auxiliary workshops

The production program of the auxiliary workshops of a printing enterprise is formed on the basis of the needs of its own main production and accepted applications from other enterprises, taken into account in the product sales plan. Auxiliary production services include the following departments: mechanical repair, transport, energy, paper preparation workshop, and tool departments for machine-building enterprises.

The scope of repair work for the enterprise is determined depending on the amount of equipment, its repair complexity and degree of security. When drawing up a repair shop program, only equipment that is repaired using our own resources is taken into account.

The volume of work of the transport service is determined depending on the total number of transportations and cargo turnover. Based on the volume and structure of the planned cargo turnover, the internal cargo turnover, the volume of loading and unloading operations are determined, the number of workers, the wage fund, etc. are calculated.

Get full text

Tutors

Unified State Exam

Diploma

Internal cargo turnover is determined by the volume of inter-shop transportation. The calculation is based on the production plans of the enterprise and workshops, plans for the supply of materials, semi-finished products, removal of finished products and waste.

The scope of work of the energy service is determined in accordance with the needs of the main workshops of the enterprise for various types of energy. The basis for calculating the required amount of energy is: the production and implementation plan for the main production, the norms of energy consumption per unit of planned production, the norms of expenditure on auxiliary services, the norms of losses in the energy conversion process, etc.

The scope of work of tool departments is developed on the basis of the total need for tools to perform work in the main production, replenish the stock of tools and satisfy external orders.

6.3.5.

Production capacity of the enterprise

The production capacity of an enterprise (workshop or production site) is characterized by the maximum quantity of products of appropriate quality and range that can be produced per unit of time with full use of fixed production assets under optimal operating conditions. Production capacity, when correctly determined, becomes a reliable guide in planning and assessing the activities of an enterprise.

The amount of production capacity depends primarily on the capacity of fixed assets and the degree of their use. The capacity of production (technological) equipment has the least impact on production capacity.

Production capacity is measured in physical units, and in some cases - in units of utility of products or in monetary terms.

In contrast to the design, the planned production capacity of operating enterprises is calculated based on the applied technological processes, the available equipment and available production space as values already specified, and the volume of output according to the planned nomenclature is the desired value, established under the conditions of full use of the resources available to the enterprise .

The production capacity of an enterprise is calculated as the sum of the production capacities of the production units that are part of this enterprise. This is a dynamic quantity, changing under the influence of various factors. Therefore, it is calculated in relation to a certain period of time and even to a calendar date. Power is determined at the beginning of the planning period - input power and at its end - output power.

Power at the end of the planning period is calculated using the formula

Mk = Mn + Mc + Mr + Mo + Miz - Mv,

where Mn is production capacity at the beginning of the planning period; Mc - capacity input as a result of the construction of new and expansion of existing enterprises; Мр is the increase in capacity due to the reconstruction of existing enterprises; Mo - increase in power as a result of technical re-equipment and other organizational and technical measures; Miz - increase or decrease in power due to changes in product range; Mv - reduction in power due to its retirement.

In addition to the input and output powers, the average annual power is also determined by the formula

where Tc, Tr, To, Tiz, Tv are the validity periods of the corresponding capacities from the moment they are put into operation until the end of the plan year.

The ratio of planned or actual production output to the value of production capacity is called the production capacity utilization factor Kis:

Kis = Vpl(f)/Mcr,

where Vpl(f) is the planned or actual volume of production in natural units.

Tasks and structure of the repair service

There are two types of production processes: main ones, the purpose of which is to manufacture products that are the subject of national economic turnover, auxiliary processes, which result in the creation of products used in the main production, and servicing processes, which involve the performance of work to ensure the uninterrupted running of the main production.

Work on the care and supervision of equipment, its adjustment, repair and modernization are considered service processes.

It is necessary to define what repair is. Repair is a set of operations to restore the serviceability, performance or service life of equipment or its components.

Along with this concept, the concept of “maintenance” is also used.

Maintenance is usually called a set of operations to maintain the functionality or serviceability of equipment when it is used for its intended purpose, during waiting, storage and transportation.

To carry out all types of work to organize rational maintenance and repair of equipment and other types of fixed assets, repair services are created at enterprises.

Get full text

The main tasks of the repair facility are:

1) organization of such a system for operation and repair of equipment that would allow maintaining the equipment in working condition;

2) systematically improving the culture of operation, care and routine maintenance in order to extend the service life of parts, increase the overhaul period of the machine, and reduce the volume of repair work;

3) reducing the labor intensity and cost of repair work while increasing their quality;

4) certification, certification and modernization of equipment.

The structure of the repair service depends on a number of factors: the type and volume of production, its technical characteristics, the development of cooperation in carrying out repair work, the centralization system, etc.

The repair service of a large and medium-sized enterprise includes the chief mechanic's department (CHD), a mechanical repair shop (RMS), shop repair services, and a general plant warehouse for spare parts and components (Fig. 1).

Rice. 1 Structure of the enterprise’s repair service

The chief mechanic department is headed by a chief mechanic who reports directly to the chief engineer of the plant.

As a rule, the following functional divisions are created as part of the OGM: a preventive maintenance bureau (PPR), a design and technology bureau, a planning and production bureau and a crane equipment group.

The PPR bureau includes groups: inspection, equipment accounting, spare parts and repair and lubrication facilities.

The inspection team plans, controls and takes into account the implementation of repair work of all types; inspects proper operation and develops instructions for maintaining equipment.

The equipment accounting group carries out certification and accounting of equipment of all types, monitors its movement, monitors the state of storage and quality of conservation of uninstalled equipment, and conducts an annual inventory.

The spare parts group establishes the nomenclature, service life, consumption rates and limits on spare parts and purchased materials, plans the production of spare parts and manages parts inventory.

The repair and lubrication group monitors the implementation of the equipment lubrication schedule; sets limits on cleaning and lubricating materials and on the collection of used oil and its regeneration.

The Design and Technology Bureau carries out all technical preparation of the PPR system and repair work of all types, including modernization; ensures the compilation of drawing albums and their storage for all types of equipment.

The production planning bureau plans and controls the work of the mechanical repair shop and shop repair services, carries out material preparation of repair work, draws up reports on the implementation of repair work plans for the plant, analyzes the technical and economic indicators of the plant repair service, identifies unproductive costs, develops measures for their elimination.

Get full text

The crane equipment group monitors the operation and condition of all lifting and transport mechanisms, plans and controls the implementation of repairs of all types.

The mechanical repair shop is the main material base for the repair service of the enterprise. It is equipped with a variety of versatile equipment and highly skilled workers. This workshop carries out all the most complex work on equipment repair, production and restoration of replacement parts, as well as equipment modernization work.

Shop repair services are created in large main workshops of the plant only when using decentralized and mixed systems for organizing repair work. Services are run by shop mechanics.

The general plant warehouse of spare parts and components stores and records all material assets necessary for carrying out all types of repairs of equipment and lifting vehicles.

The staff of engineering and technical workers and employees of the enterprise's repair service is established depending on the number of repair units of equipment in the plant as a whole.

Tasks

energy management of the enterprise: - ensuring uninterrupted supply of production with all types of energy; — the fullest use of the power of energy devices and their maintenance in good condition; — reducing costs for consumed types of energy.

Depending on the characteristics of technological processes at enterprises, various types of energy and energy carriers are consumed, to provide which an energy service is created. These are electricity, thermal energy (superheated steam, hot water), compressed air, gases (natural gas, carbon dioxide, argon, nitrogen, chlorine, oxygen, hydrogen), water of varying degrees of purification, as well as centralized heating systems, sewage systems (storm water, sewage , fecal, chemically contaminated), ventilation and air conditioning.

An approximate structure of the energy service is shown in Fig.

Rice. 9.3. Structure of the enterprise's energy service

Functions of the enterprise energy service:

— development of standards relating to the energy service; — planning the need for all types of energy and energy carriers, drawing up the energy balance of the enterprise; — equipment maintenance planning; — planning the need for spare parts; — organization of production (supply) of the enterprise with all types of energy; — operational planning and dispatching of the enterprise’s supply with all types of energy; — organization of equipment repair work; — development of technical documentation for installation and repair work of equipment and energy communications (networks); — organization of maintenance of power equipment, networks, communication lines; — control over the quality of repair work; — organizing installation and commissioning of new equipment, dismantling and recycling of decommissioned power equipment; — supervision of equipment operation rules; — control over the consumption of all types of energy.

Calculation of energy needs and energy balance of the enterprise

The organization and operation of the energy sector are based on planning energy production and determining the sources of its coverage. The need for energy resources is established on the basis of their consumption rates and the annual production program.

In addition to energy consumption for production purposes, its costs for lighting, ventilation, heating, as well as energy losses in factory networks are taken into account. The need for process energy is calculated based on consumption rates for operations or types of equipment.

Tasks of the transport sector

— ensuring uninterrupted transportation of all cargo in accordance with the production process, maintaining vehicles in good working order, reducing costs for transport and loading and unloading operations.

Rational organization of transport facilities is a prerequisite for reducing production costs. Depending on the characteristics of technological processes and types of production, the enterprise uses various vehicles.

The classification of the enterprise's vehicles is given in table. 9.2.

Table 9.2

Classification of enterprise vehicles

| Sign | Characteristic |

| 1. Application area | 1.1. External transport for connecting the enterprise with external transport systems: - railways; — airports; — river and sea ports and other enterprises 1.2. In-plant (for moving goods between workshops, sections, workplaces): - |

| 2. Type of vehicle | 2.1. Wheeled transport: — railway; — automobile; — forklifts; — electric transport. 2.2. Transport conveyors. 2.3. Monorails. 2.4. Pipeline transport. 2.5. Pneumatic transport. 2.6. Robots |

The structure of an enterprise's transport service depends on the characteristics of the production process, type of production and volume of output.

The approximate structure of a developed transport service of a machine-building (instrument-making) enterprise is shown in Fig. 9.4.

Rice. 9.4. Structure of the enterprise transport service

Functions of the enterprise transport service:

— development of standards used in the transport service; — planning needs for all types of transport based on calculations of freight flows and turnover; — planning of preventive maintenance of vehicles; — planning the need for spare parts and their acquisition; — operational planning and dispatching of the enterprise’s provision with all types of transport; — provision of production processes with vehicles; — organizing inspections and repairs of vehicles; — organization of traffic safety; — organization of vehicle maintenance (refueling, washing, etc.); — organizing the acquisition of new vehicles, their registration with government agencies, obtaining licenses for the transportation of goods and people, write-off and disposal of vehicles.

For effective planning of vehicle needs, the enterprise's cargo turnover and cargo flows are determined.

Freight turnover

- this is the sum of all cargo moved in an enterprise over a certain period of time (or the sum of all cargo flows of the enterprise).

Freight flow

— the amount of cargo (t, pcs, kg) moved in a certain direction between workshops and warehouses over a certain period of time.

Freight flows are calculated based on: - types of goods moved; — points of departure and delivery; — distances between points; — volumes of transported cargo; — frequency and regularity of transportation.

Get full text

Transportation is divided into one-time and route transportation.

One-time transportation

— transportation for individual non-recurring orders (applications).

Route transportation

— permanent or periodic transportation on certain routes.

One of the methods for determining the volume of cargo flows and cargo turnover of an enterprise is to compile a checkerboard sheet (Fig. 9.5).

This statement reflects all movements of cargo. The sending workshops and warehouses are listed vertically, and the receiving workshops and warehouses are listed horizontally in the same order.

Each workshop and warehouse is represented by a column and a line. The column totals show the total receipt of goods in a given workshop, the row totals show the amount of cargo dispatched. The sum of the totals of columns or rows for all workshops and warehouses reflects the amount of internal cargo flows.

| Sending workshops | 1 | 2 | 3 | 4 | 5 | Amount of cargo receipts in workshop P (total graph) |

| Recipient workshops | ||||||

| 1 | /////// | — | — | — | — | PC1 |

| 2 | — | /////// | — | — | — | PC2 |

| 3 | — | — | /////// | — | — | PC3 |

| 4 | — | — | — | /////// | — | PC4 |

| 5 | — | — | — | — | /////// | PC5 |

| Amount of goods sent from the workshop (total lines) | Freight turnover of the enterprise |

Rice. 9.5. Chess sheet of enterprise cargo flows

The number of vehicles is calculated both for inter-shop transportation and for intra-shop and inter-operational transport systems.

The main directions for improving the transport sector at enterprises are: - mechanization and automation of transport operations in combination with their high organization; — use of standardized packaging (including returnable); — introduction of a unified production and transport (integrated) technology; — specialization of inter-shop transport means according to the type of cargo transported; — organization of container transportation; — implementation of automated transport management systems.

Warehousing tasks

The main tasks of warehousing are: — organizing proper storage of material assets; — uninterrupted maintenance of the production process; — shipment of finished products.

Warehousing structure

(Fig. 9.6) depends on the specifics of the production process, type of production and volume of output.

Functions of warehouse departments:

— work planning; — acceptance, processing (including sorting) of cargo; — organization of proper storage (creating conditions to prevent spoilage; maintaining the required temperature and humidity); — constant monitoring and accounting of the movement of material assets; — timely provision of the production process with materials, components, etc.; creating conditions to prevent the theft of material assets; — strict compliance with fire safety measures (especially in warehouses of fuels and lubricants, flammable liquids, paints and varnishes, rubber products, chemicals, etc.); — completion of finished products, their preservation, packaging, preparation of shipping documentation and shipment.

Rice. 9.6. Warehousing structure

Mechanization and automation of warehouse work

— the main direction of improving the organization of work related to the storage of material assets and their transfer to production. A modern warehouse is a complex facility consisting of vertical shelving structures (normal height is up to 10 meters or more); automatic stacking machines with program control, special containers, reloading devices, technical means of automatic warehouse management systems, etc.

Get full text

Vertically closed (cradle) warehouses with program control have become widespread, they occupy small production areas, but have a fairly large capacity due to their vertical location.

In modern industrial production, transportation and storage processes are increasingly integrated into a single automated complex controlled by a computer.

The logistics service is headed by the MTS (OMTS) department. OMTS task

— uninterrupted material support of production in accordance with the production plan. The structure of OMTS is shown in Fig. 9.7.

Rice. 9.7. Structure of the MTS enterprise service

Main functions of OMTS:

— development of standards for reserves of material resources; — planning the need for material resources and linking it with the production plan and inventory standards; — search for suppliers, assessment of supply options and selection of suppliers based on the criteria of quality of supplied materials, reliability of suppliers, prices, terms of payment and delivery, transportation and procurement costs, etc.; — concluding supply contracts; — organization of work on the delivery of material resources, control and operational regulation of the implementation of supply contracts; — organization of acceptance, processing and storage of material resources; — operational planning and regulation of production supply with material resources; — accounting, control and analysis of the consumption of material resources; — supervision over the rational use of materials in production.

MTS planning.

A material and technical supply plan is a set of settlement documents that substantiate the enterprise’s need for material resources and determine the sources of their coverage. It is compared in the form of the MTS balance sheet.

The MTS plan is developed taking into account: - production program; — standards for reserves of material resources; — norms of consumption of raw materials, materials, semi-finished products, fuel, components; — plans for capital construction, reconstruction, preparation for the production of new products, repair and operation of equipment, buildings, structures, household facilities, etc.; — balances of material resources at the beginning and end of the planning period; — established and newly established relationships with suppliers; — prices for all types of material and technical resources.

The need for materials for main production (Gm.bas) is determined by the formula

where Qi is the volume of production for each item (pieces); ni is the rate of material consumption per product, taking into account technological losses (natural units); m is the number of product items.

The total need for specific materials (Gm) is determined by the formula

where Zn.z is the material supply rate; Zm.f - actual availability of materials at the enterprise; Gm.n.p - the required amount of materials to change work in progress; Gm.ex - the need for materials for repair, maintenance and other needs.

The need for material resources is determined by the costs of: - main production, including the production of components and spare parts; — production of technological equipment and tools; — production of non-standard equipment and equipment modernization; — carrying out research and development work (including the production of prototypes and experimental work); — reconstruction of workshops and areas; — repair and maintenance needs; — capital construction; — work in the social, cultural and everyday spheres; — creation of reserves.

Tool farming

Tools (technological equipment) are any types of measuring, cutting and assembly tools, molds, dies and various devices. The set of departments that are responsible for the acquisition, design, manufacture, restoration and repair of technological equipment, as well as their accounting, storage and delivery to workplaces, is called a tool department. It includes the following structures:

- tool department – provides supplies of fixtures and tools, as well as their design;

- tool shop – manufactures, repairs and restores special equipment and tools;

- central tool warehouse – records, stores and issues equipment and tools;

- workshop storerooms - designed to provide workers of certain workshops with tools.

Energy economy

All technical means necessary to maintain an uninterrupted supply of various types of energy to an enterprise are called energy management. It, in turn, includes the following farms:

- thermal power – steam and air networks, boiler rooms, sewerage, water supply, compressors;

- electric power – step-up and step-down substations, transformer and generator sets, electrical networks, batteries;

- gas – gas generator stations and gas networks, ventilation and refrigeration compressor units;

- low-current – radio network, automatic telephone exchange, other types of communication;

- furnace – thermal and heating furnaces;

- power equipment repair shops.

The costs of auxiliary production include the need for energy, which is determined depending on the production plan, taking into account the norms of energy and fuel consumption, the norms of losses in pipelines and networks, etc.

Transport industry

The totality of enterprise funds that are intended for the transportation of materials, raw materials and semi-finished products, waste, finished products and any other goods both outside the enterprise and on its territory is called transport facilities.

Depending on its purpose, transport can be external, inter-shop, intra-shop and intra-warehouse.

According to its mode of action, it can be continuous (pipeline, conveyor) or discontinuous (forklift, car).

By type they distinguish road, rail, water, in-plant (rail and trackless) transport.

As for the transport sector, the organization of auxiliary production requires solving a number of important issues:

- volume of cargo turnover and cargo flows,

- transportation,

- choice of transport type,

- loading and unloading operations.

Storage facilities

It includes warehouses specialized by types of material resources, organized on the basis of the requirements for storage and processing of the latter.

A warehouse is a production facility or area that is intended for short-term or long-term placement and storage of material assets, stocks of raw materials, semi-finished products and materials, as well as for performing operations to prepare the above for production.

Warehouses are production, supply, workshop, general plant, sales, universal and specialized, open, semi-closed and closed.

When organizing warehouse auxiliary production, it is necessary to determine the size of warehouses and their number, their location, and select the most rational types of warehouse inventory and equipment in each specific case.

When calculating the area of warehouse premises, it is necessary to take into account not only the “useful” territory intended for the direct storage of raw materials or finished products, but also the area of passages, aisles, areas for sorting and releasing goods or raw materials, loading and unloading.

Documentation of auxiliary production services

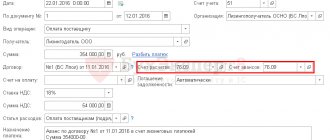

All work and services provided by auxiliary productions are documented with the following documents:

- acceptance certificates for objects that have been repaired;

- invoices – display the number of tools and equipment manufactured and delivered to the warehouse;

- waybills – reflect the volumes and route of transportation of the transport sector;

- certificates issued by the chief technologist or mechanic - reflect the scope of work and services provided by simple production.

The services that were provided by auxiliary departments to each other are called counter services. They are valued in accounting at planned cost. Services that were provided to main consumers are valued at actual shop costs.

Auxiliary production in construction

Often, construction companies organize auxiliary units for the manufacture of building materials and structures, repair of fixed assets and for other purposes. What features should be taken into account when creating them? What is the accounting procedure in these divisions?

Organization of accounting: no special requirements

The specific procedure for maintaining records for auxiliary production is determined by companies independently by accounting policy. There are currently no regulatory requirements for organizing such accounting, other than the general requirements for maintaining accounting records in a construction company. About 20 years ago or more, when the organization of accounting was strictly regulated by departmental instructions, requirements for maintaining records of auxiliary production existed. Now they do not have a normative character. Nevertheless, as an example, we will give the procedure for keeping records of auxiliary production in construction organizations that was in force in past years. It can be taken as a basis for organizing this accounting in modern conditions.