The employer has the right to determine the calculation procedure and form of working time balance independently. As a rule, to calculate it it is necessary to determine the number of working days and hours, the duration of the working day and calculate the useful fund of working time.

Working time is the time during which the employee, in accordance with the internal labor regulations and the terms of the employment contract, must perform labor duties, as well as other periods of time that, in accordance with labor legislation, relate to working time (Article 91 Labor Code of the Russian Federation).

To increase the efficiency of using the working time fund and determine the planned number of employees, the working time balance is used.

Components of working time balance

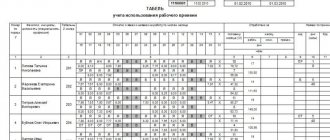

This analysis contains expected indicators and actual use of working time. Units of measurement – man-days / man-hours.

Elements of analysis:

- calendar fund = number of days in a year;

- nominal (time) = all days minus weekends and holidays;

- maximum possible = nominal minus vacation days;

- attendance = maximum possible minus no-show;

- actual = turnout minus downtime.

Such a report is compiled monthly for each structural unit. Subsequently, the planned time is compared with the actual time. Indicators are analyzed in absolute values and in coefficients:

- fact. time /max. possible;

- no-show/time sheet or max. possible;

- appearance /Max. possible.

Thus, the main task of balance is:

- Increasing the efficiency of using the working time fund.

- Determination of the planned number of specialists.

The essence of the concept of “working time fund”

In a broad sense, the working time fund (WF) is an indicator containing the expected volume of hours available in the future for carrying out certain work. This value can be calculated both within the entire organization and relative to just one employee.

The main purpose of calculating the PDF is, first of all, planning the use of work resources and capabilities. Having data on potentially available days and hours of labor, it is realistic to calculate planned productivity. In the future, based on analysis and comparison of the latter with actual indicators, it is possible to identify losses and take steps to increase employee productivity. The result will be an increase in the efficiency of a particular organization as a whole.

It is also important to understand that the calculation of the working time fund is always based on information for each individual employee. In particular, when determining how long an employee can work in the future, a number of special factors are taken into account. Namely:

- physical capabilities of a person;

- requirements of the Labor Code of the Russian Federation;

- company capabilities aimed at harnessing the potential of the working citizen.

It is allowed to determine the working time fund in both hours and days. Accordingly, the units of its measurement are either man-days or man-hours.

Expert commentary

Kireev Maxim

Lawyer

At the same time, when calculating the FER indicator, periods of employee illness for a specific period, as well as parental leave, being late for work, holidays and other factors must be taken into account. The value of the working time fund in each of these cases is subject to change downwards by the corresponding number of days or hours.

Working time balance calculation

Let's say the company already exists. There is a staffing table, a vacation schedule, and time sheets for previous periods. You need to calculate:

- nominal fund of working hours;

- hours falling on vacation;

- maximum possible fund;

- turnout planning fund.

The “head” of the educational balance looks like this:

- Time sheet values are taken from the work schedule of a particular specialist. For example, December 2020 has 31 calendar days. We take away holidays - we get 28. Forty-hour work week, five-day week - 20 working days or 160 working hours.

- The number of “vacation” days is taken from the vacation schedule. If an employee has a vacation planned for the analyzed period, then to calculate the maximum number of working hours, planned vacations are subtracted from the time sheet values.

- Planned vacation is compared with scheduled working days. The table reflects the days and hours falling on work shifts.

- To calculate the time of attendance, it is necessary to predict the days of no-show. It is impossible to do this as accurately as possible. Therefore, let's take the average percentage of no-shows for the previous quarter. We subtract the resulting value from the maximum possible fund. The result is a planned turnout fund.

Let's make a forecast of the number of working hours for a conditional month.

In the “Maximum possible time” column, the calculation is performed automatically. Enter the formula: = F4 – H4 (time sheet values minus planned leave). For days and hours respectively.

To calculate no-show hours, average no-show rates are needed. It is most convenient if time tracking is also done in Excel. “Attendances” and “absences” are calculated monthly for each employee.

Then, when drawing up a balance sheet for a new period, you can enter a formula in the “Attendance time” column with reference to “Accounting for working hours.” for the previous 3 months.

The same algorithm is used to fill in data for all employees and departments. Formulas are copied to the entire column.

Subsequently, based on the balance sheet, you can create an analytical table to compare planned and actual indicators.

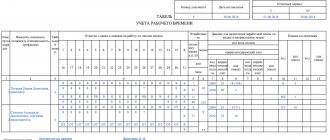

Time balance of one average worker

Balance sheets are drawn up per person, usually at industrial enterprises.

Stages of compilation:

- Determination of the number of working days. Holidays and weekends, absences from work for valid reasons, and downtime (if they took the whole day) are subtracted from the number of calendar days.

- Calculation of the duration of the working day. Temporary losses established by law (for nursing mothers, for those working in difficult conditions, etc.) are subtracted from the nominal duration.

- Calculation of the effective time fund of one average worker.

Let's enter the indicators and known values into the Excel table:

We will find all other numerical values for the indicators using the formulas:

Let's divide by “mathematical” actions:

- First, let's find the working time budget: shift duration * available days.

- With a five-day work week, the numerator is: established shift duration * worker budget. hour + 5 * temporary losses.

- The denominator is the sum of the budget and losses.

Calculation result:

Actual and standard working time balances

We expand the table with the standard balance - add a column with actually used working time for the period and with deviations.

We enter the actual values. We find deviations using formulas. The analysis is ready.

The principle of calculating the nominal working time fund

The nominal working time fund, or, as it is also called, the time fund, indicates the expected number of days the employee will go to work in accordance with the schedule. This takes into account holidays, the right to which is granted to working citizens on the basis of the Labor Code (Article 112). Weekends are also taken into account. For example, with a five-day work week, this could be Saturday and Sunday.

Article 112 of the Labor Code of the Russian Federation

“Non-working holidays” (more details)

At the same time, the nominal FRF is based on one or another calendar period. It could be as follows:

- year;

- quarter;

- month.

The latter period is used in most cases. It is important when calculating wages, as well as when identifying the ratio of days actually worked to the established production rate.

To calculate the nominal PDF, the following algorithm is used:

- subtract the total number of holidays and weekends from the number of calendar days for the required period;

- multiply the resulting value by the number of employees of the enterprise.

Expert commentary

Shadrin Alexey

Lawyer

If the calculation is made in man-hours, then not only holidays and weekends, but also shortened pre-holiday days should be taken into account. For the latter, the shift is reduced by 1 hour.

The nominal FRF indicator is directly related to the production calendar compiled annually for Russia. The calendar contains information about all holidays and weekends, as well as working hours.

For the current year, the calendar fixes the following standard:

| Calendar days | 365 |

| Working days | 247 |

| Weekends and holidays | 118 |

But for a 40-hour week, the hourly norm of permissible working time will be 1 thousand 970 hours. At 35 hours – 1 thousand 772 hours.

In general, the production calendar is of significant importance for accountants and HR specialists throughout Russia. With its help, wages are calculated, a work schedule is drawn up, sick leave is paid and vacation is calculated.

Production calendar for 2020

vanyok.okis.ru

Working time balance is a system of indicators that characterizes the total resource and use of an employee’s time in production. It is usually formed for the year in the form of a table. It can be represented by the expressions:

Fк = Fн(дн) + Дп + Дв, (8.21)

Fef = Fn - (Do + Add + Drr + Dbol + Dgo) * Tcm * K, (8.22)

where FC – calendar fund of time, days;

FN(DN) – nominal time fund, number of working days;

FН – nominal working time fund, hours;

FE – effective time fund on average per worker, hours;

Дп and ДВ – number of holidays and weekends;

DO, DRR, DBOL, DGO - the number of days, respectively, of regular and additional leave, training leave, in connection with the birth of a child, absence due to illness, performance of state and public duties;

TSM – average duration of a work shift, taking into account reductions on pre-weekends and holidays, hours;

K is the coefficient of use of shift working time (taking into account its reduction for workers employed in difficult and harmful robots, teenagers). Absences with the permission of the administration, absenteeism, round-the-clock and intra-shift downtime are taken into account only in the reporting balances.

Labor cost standards are established values of labor costs for producing a unit of product or producing a product per unit of time, for performing a given amount of work or servicing means of production in certain organizational, technical and climatic conditions.

Standards for labor costs are classified depending on the units of measurement of labor - standards for time, production, maintenance, management; methods of determination - technically sound and experimental-statistical; degree of differentiation and other characteristics.

Time standard is a regulated amount of working time, established for the production of a unit of product (labor) by one or a group of workers (team) of appropriate qualifications in certain organizational, technical and climatic conditions. Determined in man-minutes, man-hours, man-days using the formulas:

Нв = tpc + tp-h, (8.23)

tsht = to + tv + tobsl + totd + tp, (8.24)

where NV is the time standard;

tШТ – standard piece time;

tП-З – norm of preparatory and final time;

tO, tB, tOBSL, tOTD, tP – time, respectively, for main, auxiliary, workplace maintenance, rest and personal needs, breaks for organizational and technical reasons (regulated)

The rate of piece-calculation time is determined by the formula

Nsh-k = tsht + ( tп-з / n ), (8.25)

where n is the number of products (parts) in the batch;

tP-Z – preparatory and final time for a batch of products.

Production rate is a set amount of work (number of units of production) that one employee or group (in particular, a team) of appropriate qualifications is required to perform (manufacture, transport, etc.) per unit of working time in certain organizational, technical and climatic conditions conditions. It is measured in natural units and is a value inversely proportional to the standard of time.

The standard time for a batch of products is a regulated amount of working time for the production of a certain number of products (batch) by one or a group of performers of appropriate qualifications in certain organizational, technical and climatic conditions. Set in man-minutes, man-hours, man-days.

Maintenance time standard is the time established for servicing a unit of equipment, production areas or other production facilities under certain organizational, technical and climatic conditions.

Balance of working time costs

Grouping of working time costs of the same name

Observation sheet of individual photograph of working time

| No. | What was observed | Current time. | Worker costs, min | Overlapping time, min | Index | Actual output |

| b | ||||||

| Came to work place | 7.00 | |||||

| Receives a task | 7.04 | PZ | ||||

| Unfolds the tool | 7.10 | 6 | PZ | |||

| Resets the machine | 7.24 | PZ | ||||

| Processes a part | 8.30 | OP | ||||

| etc. | ||||||

| Total | ||||||

| Date2.10.99 | Shift I | Observed by Sidorov A.P. |

Processing of observation results consists of calculating the duration of working time expenditure for each of the marked categories of working time expenditure by subtracting the current time of the previous measurement from the current time of each subsequent measurement. After this, for all measurements in the “Index” column, according to the accepted classification, a brief designation of this type of cost or loss of working time is entered. Further processing consists of selecting and grouping time expenditures of the same name (Table 2).

For analysis, actual and standard working time balances are compiled (Table 3). When drawing up a regulatory balance, all irrational costs and direct losses of working time are eliminated, thereby increasing operational time. Preparatory and final time, time for organizational and technical maintenance, time for rest and personal needs are calculated as a percentage of the received operational time according to the relevant standards.

table 2

| No. | Cost Category Index | Repeatability of costs | Total cost, min | Incl. overlap time, min | Share of costs in total observation time, % |

| Tpz | |||||

| Top | |||||

| Tobs | |||||

| Totd | |||||

| Tpnt | |||||

| TPND | |||||

| Total |

Table 3

| No. | Working time cost category index | Actual balance | Regulatory balance | Extra costs | Regulatory balance | ||

| min | % | min | % | min | % | min | % |

| Tpz | |||||||

| Top | |||||||

| Tobs | |||||||

| Totd | 0,4 | ||||||

| Tpnt | — | — | — | — | |||

| TPND | — | — | — | — | |||

| Total |

As a result of comparing the actual time spent with the standard ones, unnecessary costs of preparatory and final time, time of organizational and technical maintenance, time for rest and personal needs are identified that need to be reduced. The reasons that caused irrational and unnecessary costs, losses of working time are studied and the truly necessary costs are established, taking into account the amount of work that could be performed by a worker during the observed period in the absence of unnecessary costs and losses of working time.

By comparing data from actual and standard working time balances, the following coefficients are determined:

• useful use of working time:

where Тпз — preparatory-final time;

Top - operational time;

Tobs - workplace servicing time;

Tnotd - time of breaks for rest and personal needs according to the standard;

Tpt - time of breaks established by technology and organization of the production process;

Tnable—observation time;

• beneficial use of equipment:

• loss of working time depending on the worker:

where Tpnd - breaks in work for reasons depending on the worker;

• loss of working time for organizational and technical reasons:

where Tpnt are interruptions in work caused by organizational and technical reasons.

A possible increase in labor productivity by eliminating losses and waste of working time is also determined:

or

where Tfop and Tnop are operational time for actual and regulatory balances;

Tfotd and Tnotd - actual and standard time for rest and personal needs.

The analysis of data from individual photographs of working time ends with the development of organizational and technical measures to eliminate the causes of loss of working time and to improve the organization and standardization of labor. These measures must be formalized by order of the workshop or included in the general plant plan, indicating the deadline for their implementation and responsible performers.

Timing

Timing is a type of observation in which cyclically repeating elements of operational work are studied, as well as individual elements of preparatory and final work or workplace maintenance work.

The purposes of timing are:

• establishing time standards and obtaining data for the development of labor standards;

• study and implementation of advanced techniques and methods of work;

• checking the quality of current standards;

• identifying the reasons for non-compliance with standards by individual employees;

• improving the organization of the labor process in the workplace.

There are three methods of timing:

• continuous - according to the current time, when all elements of operational time are measured, cyclically repeating in a certain order;

• selective - when individual elements (work methods) of an operation are measured regardless of their sequential execution;

• cyclic - when operations are studied that have a very short duration, which does not allow them to be visually measured without combining them into groups, each of which is periodically repeated in each cycle and in a certain sequence.

The accuracy of time measurements when conducting timing observations depends on the duration of the execution of the studied elements of the operation. For an operation element duration of up to 10 s, measurements are carried out with an accuracy of 0.1 s, for longer durations - up to 0.2 s.

Time-lapse observations should be carried out 45-60 minutes after the start of work and 1.5-3 hours before the end of the working day (and all observations must be completed no later than 30 minutes before the end of work). The number of measurements taken each time should be half the recommended number for the entire shift. Moreover, observations should be carried out not only in day shifts, but also in other shifts, except in cases where this is impossible due to failure to perform standardized work in other shifts or due to the rare repetition of the operation under study.

Timing includes three stages:

• preparation for observation;

• conducting observation;

• processing and analysis of observation results.

Preparation for observation covers several stages.

Firstly, depending on the purpose of timing, the object of observation is determined. To identify the most efficient work practices, observations should be made of frontline workers. If the purpose of timing is to establish standards or obtain data for the development of standards for identical operations performed by several workers, several people are selected who have a group average level of fulfillment of production standards for the last 3 months and work experience in the specialty of 4-20 years (sample size depends on number of workers group). If there are 2-3 people, it is enough to observe 1 worker; if there are 4-5 people - for 2; if there are 6-8 people - for 3, etc.

If the purpose of timing is to identify the reasons for non-fulfillment of production standards, observation is carried out on workers who do not meet production standards, and the results obtained are compared with the standards and time spent according to the timing data of workers who exceed these standards.

Secondly, it is necessary to become familiar with the operation that is subject to timing. Its structure and methods of implementation are studied. The operation is then broken down into its component elements. When dismembered, the technological sequence of performing each element is revealed (with continuous timing) and the possibility of eliminating unnecessary techniques or unnecessary elements.

The degree of division of the operation depends on the type of production, the accepted systematization of the elements of working time costs, the objectives of the study, and the possibility of measuring the duration of each element.

Thirdly, the beginning and end of each element of the operation are determined, that is, fixation points. Signs for determining fixation points can be the clearly perceived visually or auditorily beginning and end of a worker’s action or movement. The starting and ending fixing points of each element of the operation are distinguished. When observing the current time, the fixing point of the end of the element is also the starting point of the subsequent element.

Fourthly, factors influencing the duration of each element of the operation in specific production conditions are identified. Such factors may depend on the design of the equipment, the weight and configuration of the products, manufacturing technology, operating modes of the equipment, production organization, labor and workplace.

Fifthly, according to Table 4, the required number of measurements that need to be carried out during one observation is determined. One measurement is a one-time recording of the execution time of that element of the operation for which time costs need to be determined.

Individual photograph of working time Processing the results of an individual photograph of working time consists of constructing a balance of working time, calculating indicators of its use and coefficients for increasing labor productivity by bringing it to standard working time costs.

[p.28] Photography consists of a sequential recording of all costs and losses of working time and current time for each type of cost. To determine the duration of individual costs, its value for the previous element of work is subtracted from the current time indicator. Then each type of cost and loss is assigned an index in accordance with the classification of working time costs. Costs of the same name are combined into groups, i.e. they compile a summary of the costs of working time of the same name, and on its basis the actual and standard balances of working time are determined. By analyzing these balances, the following coefficients for the use of working time are determined [p.110] The entire process of photographing working time includes preparing and taking photographs, processing and analyzing the data obtained, developing organizational measures to improve the organization of work and establishing the causes of lost working time, drawing up a standard balance of working time time. [p.141]

For analysis, actual and standard working time balances are compiled (Table 9). When drawing up a regulatory balance, all irrational costs and direct losses of working time are eliminated, thereby increasing operational time. Preparatory and final time, time for organizational and technical maintenance, time for rest and personal needs are calculated as a percentage of the received operational time according to the relevant standards. [p.152]

By comparing data from actual and standard working time balances, coefficients are determined [p.154]

The actual and standard balance of working time, taking into account the elimination of identified losses, is given in table. 10.14. [p.447]

| Table 10.14. Actual and standard working time balances |

Elements of the same name Index Duration according to measurements, min Number of observations Actual balance of the working day Standard balance of the working day [p.180]

Example. The production program for melting solid charge through the annealing smelting process is 510 thousand tons per year; the productivity of each of the operating reverberatory furnaces for melting solid charge is 750 tons per day; the planned operating time of each furnace is 340 days. The standard staff of workers per shift for furnace maintenance is 15 people. operating mode - three shifts; number of days of work per worker according to the planned balance of working hours - 280. It is necessary to determine the required average number of workers. [p.187]

This concludes the development of the working time balance project. Its result represents the standard value of labor costs T3 at a given workplace. In the example given (Table 23) T3 = 307 min. Relating this value to the duration of the shift (480 minutes), we obtain the norm for the number of NPs for a given workplace R = 307/480 = 0.64. [p.202]

In the first case, the balance of working time based on the results of photographs of the working day (shift) is compiled with a breakdown of labor costs for each group of work. The standard volume of work, the number of workers per month and the need for them per shift are determined for each group of work separately. The total need for workers to complete the entire volume of work is determined by summing the number for each group of work. [p.270]

Drawing up a working time balance (Form 1.1) allows you to identify losses (costs) that need to be reduced. The actual balance of working time is established based on observation materials. It records obvious losses of working time (losses due to the fault of the worker, organizational and technical reasons, unproductive work). The duration of the projected (normative) balance is determined according to the corresponding time standards, which makes it possible to identify hidden losses, i.e., unnecessary costs in standardized categories (preparatory and final time, time for servicing the workplace and time for rest and personal needs). [p.16]

In order to eliminate losses of working time, organizational and technical measures are being developed. In this case, the timing of the events and responsible persons must be indicated. Taking into account the elimination of time losses and irrational costs, a standard balance of working time is designed. [p.72]

The standard balance of working time for a mechanic to repair equipment is given below [p.72]

| Table 3. Actual and standard balance of working time for a mechanic |

The second group consists of all other machinery.

Here, service standards are determined based on a photograph of the working day. Based on observational materials, actual and standard balances of working time are compiled. In the regulatory balance, a special line is allocated for the time that the driver spends on servicing the main equipment. In addition, maintenance work on communications, ventilation systems and tanks is indicated separately. [p.179] The standard workload factor takes into account the time costs associated with performing on-call work and preparatory and final work. It is determined by the standard balance of working time, which is projected on the basis of data from an analysis of the actual balance of working time [p.205]

Develop a projected balance of working time using the following standard data (in minutes) [p.49]

The projected balance of the performer's working time (preparatory and final time, observation of instrumentation, sampling, - entries in the shift log, filling the tank with oil, loading the apparatus, filling the system, regulating feeds, monitoring latex drainage, bleeding gas and the duration of servicing the workplace) in the normative balance remains the same as in the actual one. The duration of a shift is reduced from 15 to 8 minutes (according to standards), i.e. by 7 minutes. The duration of casual work that does not depend on the worker is eliminated or reduced by 23 minutes, and the duration of casual work that depends on working time is reduced by 10 minutes. rest and personal needs are reduced to normal, i.e., up to 10 minutes. Total time consumption is reduced by 47 minutes. [p.79]

Standard balance of working time [p.79]

To determine the standard number of workers, below is the calculation of the balance of working time for one worker [p.89]

To calculate the standard balance of working hours of the day, time standards for preparatory and final operations, workplace maintenance, rest and personal needs approved for this type of work are used. Then the standard operating time (OP m) is determined and the standard balance of working hours of the day (shift) is drawn up. [p.95]

The actual and standard balances of working time allow us to draw certain conclusions about the actual use of the working day and the possibility of increasing labor productivity due to identified losses. [p.95]

As a result of processing, photographs of the working day constitute the actual balance of working time (Table 15) and determine the specific weight of each type of working time expenditure. The projected standard balance of working time is drawn up after a detailed analysis of working time costs, clarification of ways to improve the organization of labor, the regime of the production process and mechanization of labor, and the elimination of unproductive labor costs. At the same time, they draw up a plan to improve production efficiency. [p.263]

Photography includes observing, measuring and recording working time costs, grouping actual working time costs and drawing up an actual time balance, developing new standards and drawing up a standard time balance. New standards are developed on the basis of proposed organizational and technical measures to increase labor productivity. [p.139]

To improve the extensive use of fixed assets, measures aimed at expanding the working hours of active elements of fixed assets (drilling rigs, oil wells, etc.) are important. The basis for identifying and assessing the effectiveness of such measures are balances of the calendar fund of time, in which time costs are grouped by areas of use, and time losses are grouped by the reasons that determined them. Reserves for the useful use of time are identified on the basis of these balances by comparing actual time expenditures with standard ones (based on standardized time expenditures) and average actual time expenditures with the best indicators obtained by advanced workers or teams. [p.354]

Further processing of observation results and conclusions based on route photography materials are made similarly to the method of direct observations. The form of the actual and standard balances of working time costs is presented in table 14. [p.162]

In addition to the previously adopted notations, we denote by tj the coefficient of direct labor costs in the y-th industry, by PJ the unit price of the y-th product, by Pt the monetary equivalent of the new value created per unit of working time, by Vn the standard rate of payment per unit working time, through a - the rate of surplus product in relation to the necessary (rate of profit). Then in the balance sheet for each y product the equality must be observed [p.518]

Working day photography is carried out in the following order. After preparing for observation, which consists of a detailed study and description of the object of observation and the production environment, the observer taking photographs records all time spent without exception. At the same time, he notes on the observation sheet what work the performer performed and the time (the beginning and end of this work or downtime). Photo processing consists of determining the composition and structure of working time and identified losses, drawing up a balance of working time and designing a new, rational balance. When designing a normative balance of working time, the possibility of combining individual elements of time, eliminating unnecessary costs, eliminating unregulated breaks and other losses of working time is provided. [p.197]

To obtain the full amount of time spent at workplace T3, the projected balance of working time must include standard values for the preparatory and final time Tp., the time for servicing the workplace Hor. m, and time for rest and personal needs Totl. [p.202]

Draw up a projected balance of working time using the following standard data for total shift time (in minutes) [p.32]

Regulatory observation carried out over a full work shift using digital, graphic or mixed photographic recording can be used both to develop new production standards and as a photograph of workers’ working day or a photograph of the time a machine is used. FRD and FVIM are specifically carried out to determine the balance of working time to identify obvious intra-shift losses, as well as to eliminate shortcomings in the organization of labor and production. In addition, with the help of photographs of the working day, it is possible to determine the degree of use of workers according to their qualifications during the working day, obtain data for determining the rational composition of the team and the appropriate [p.64]

Sources of information are planned and actual working hours, labor reports, time sheets. When calculating the balance of working time, along with standard data, data is used that characterizes the actual progress of cases in previous periods (absence due to illness, time to fulfill state and public obligations, etc.), as well as data from time sheets of attendance and absences at the state university. with decoding of the latter for reasons. The balance of worker laziness is compiled for the economic entity as a whole, for each production unit and each category of workers. [p.131]

They also determine the possible percentage of improvement in the use of working time Kb by eliminating time losses due to the fault of the worker, but the fault of the administration (organizational downtime), as well as by bringing the time spent on servicing the workplace and preparatory and final work to the standard in accordance with the projected time balance ). For our example [p.169]