The most dangerous work from the point of view of fire safety, carried out inside buildings and structures, as well as on the territories of industrial facilities for various purposes, are fire processes. It should be noted that in order to carry them out, you need to obtain a special permit, which is issued by the site manager or the chief production engineer. This document is called a hot work permit.

Types of hot work

The list of hot work (HW) is quite wide. It includes not only processes in which an open flame of fire is used, but also those in which fire is only an auxiliary factor. Let's list all the types:

- gas welding, electric welding, as well as metal cutting using these technologies;

- metal soldering;

- cutting metal products and structures using power tools, during which a large number of sparks are released, which cause the fire of flammable materials;

- heating of structures or equipment during their installation/dismantling;

- heating of bitumen or bitumen mastics, which are used in construction for waterproofing structures, pipelines and other utility networks;

- cutting metal products, structures where gases and liquids are used (the latter - gasoline or kerosene).

It should be noted that a work order for performing hot work is not always necessary. If these operations are carried out in specially designated premises or fenced areas, then fire operations are carried out in them constantly without the requirement of permits. Such areas are equipped in accordance with fire safety rules, that is, with primary fire extinguishing means: fire extinguishers, sand, water and accessories (shovels, felt mats, bucket).

In other cases, a work permit must be issued. It is signed either by the manager, or the chief engineer, or the employee who is responsible for the fire safety of the facility. At the same time, the document indicates for how long it is issued (usually for one shift), where fire activities will be carried out, and who will carry them out. If work is not completed in one shift, then the permit is extended, which is noted in a special paragraph of the work order. If the work contractor has changed, this is also indicated in the permit.

Attention! The issuance of a permit for hot work must be reported to the site fire department, which must allocate its employees for control. Here an entry is made in a special journal where and when these processes will be carried out.

Work permit for hot work: registration procedure

For what period is the permit issued?

Filling out the form does not entail any difficulties - just follow the following procedure:

- In the upper right part of the work order, it is required to indicate the full name of the enterprise (any abbreviations are unacceptable), whose workers plan to carry out hot work, regardless of whether it is in an explosive area or not. Additionally, the structural unit, if any, is indicated.

- In the upper left part, the form must indicate comprehensive information regarding the management of the company, as well as the date of registration. Upon completion of the welding work by the welder, the preparer submits the form for signature to the director with the organization’s seal affixed.

- The full name of the document is indicated in the center of the sheet.

- Next, from a new line, each item separately lists: which employee has been given the assignment (the person responsible for carrying out the orders of superior management), what kind of work must be performed, the detailed location of the object (information about the actual address is entered).

- The next item should include information regarding the performer of the work: the position held (for example, a power engineer who plans to work in an electrical installation), the current level of qualifications, and the date of the last briefing. A personal signature is required.

To compile it is enough to adhere to the established rules

After this, the authorized specialist must indicate data that directly relates to the work process, namely:

- Initially, the start and end dates are indicated, in hours and minutes.

- The measures taken to ensure the maximum level of operational safety are indicated, for example, the welding machine is in good condition.

- At the next stage, the fact of coordination of the approved fire safety measures with the authorized responsible person at the enterprise is confirmed, indicating his position, initials and time of approval.

- The last point confirms the fact of undergoing additional training immediately before carrying out work in order to achieve the assigned tasks and goals.

Note! According to the established rules, a work order must be issued for all individual types of work without exception for each shift.

If it is impossible to complete the work within the previously allotted time frame, it is possible to make a note that the validity of the document is extended, but not for a longer period that was allotted before. Additionally, it is required to confirm the validity of the new provision with a personal signature. When changes are made to the composition of the team, information about this should be indicated in a specially designed table - for example, one specialist was replaced by another.

Changes are indicated in a special table of the document

Upon completion of the work, it is necessary to record this fact in a specially designated journal, with the obligatory marking of the date and time, and then submit it to the management of the enterprise for signature. Additionally, a stamp is required. The instructions are simple, a temporary permit can be issued to the entire brigade, there is no need to approve this with an Order.

An example of filling out a work permit

To avoid mistakes when filling out a document and write it out without complications, it is advisable to use an example.

Important! It can be signed out by an authorized person and must be signed.

you can here.

A blank form can be downloaded here.

Work permit

The form of the permit for hot work is shown in the photo below. This is a document that gives permission to carry out work associated with an increased fire danger. It is issued only to highly qualified workers who have undergone special training (profile technical), received a certificate (diploma or certificate), and have also completed training in the fire-technical minimum.

The permit approval, as mentioned above, is approved either by an official of the facility or by the person responsible for food safety at the facility. This relates to the question of who issues the permit for hot work at the enterprise. As for the control of ongoing operations related to fire hazards, there are a large number of employees: the workshop manager, the shift supervisor, in which this type of activity is carried out, who are responsible for the fire safety of the enterprise.

The permit is issued on a standard form; it is legalized by the fire regulations of 2012 (Appendix No. 4). There is nothing complicated in the preparation of the document. Let's look at how to do this correctly.

How is an admission order issued?

Drawing up a work order for hot work is the final stage. Before this you need:

- Think over a plan for upcoming work, which should be carried out only during daylight hours. It is taken into account that after all events are completed, the person responsible for fire safety will inspect the venue to make sure that everything is completed, there are no fires, and the place itself has been cleaned.

- The hot work site is being prepared: the area is cleared of combustible and flammable materials; if necessary, protective enclosing structures are installed in the form of screens made of non-combustible materials.

- Technological processes are stopped in places where operational procedures are carried out where fire hazardous substances are used. The tanks in which flammable liquids are stored are hermetically sealed.

- The areas are provided with fire extinguishing equipment.

- If the OR is carried out by subcontractors, then the employee responsible for industrial safety at the site checks the documents of the workers sent to carry out the OR.

An example of filling out a permit for hot work

The preparation is complete, you can proceed to registration. The procedure for issuing a work permit for hot work is to enter into the document the necessary data that relates to the workers, the place and time of the work. Here are a few main points:

- to whom it is issued;

- what type of OR (heating, welding, etc.);

- where it is carried out indicating the exact location;

- composition of performers (number of people by name);

- time: beginning and end.

The permit is signed by the employee issuing it and receiving it. As well as senior staff responsible for preparing the OR site, and heads of relevant facility services. Approved by the head of the enterprise, his deputy or chief engineer.

Learn more about the officials involved in issuing permission to conduct hot work.

- If the enterprise consists of several workshops, then the issuance is carried out by the head of the workshop where the fire activities will be carried out. This can be done by the chief mechanic, power engineer, technologist or their deputies.

- The person responsible for preparing the event area is the head of the unit where this type of event will be held.

- The person responsible for carrying out the OR is the shop engineer, shift supervisor, foreman, and foreman.

- The observers include different employees, but usually the employee responsible for the safety of the premises, employees of repair services, the shop and shift supervisor.

If the enterprise has an organized fire department, then their representatives must participate in this event.

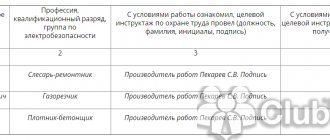

The permit form for performing hot work contains additional items and tables. They are filled out if the ORs were not completed during one shift. The main table numbered “11”, into which new employees are entered. They will carry out OR in place of those who left their shift. In paragraph “10” enter the name and position of the managerial employee with whom the replacement of employees was agreed upon.

And one more question - how long is the hot work permit kept? Its shelf life is 1 month. Usually it is collected in folders that lie in the safe or desk of the head of the workshop where the operational reviews were carried out.

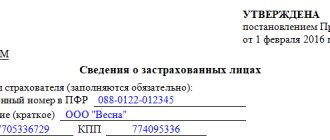

Instructions for filling

The “header” is filled in on the right side of the sheet. Information about the person who gives permission for hazardous work in this particular place is indicated here. They are usually authorized by the founder or director of the company. The date the document was compiled is also indicated here. There is space left here for the manager’s signature. This is done after the document is completely filled out. On the left side you must indicate the full name of the company, and, if necessary, its division or structure.

Next, in the center of the page you need to indicate the name of this document: “Permission to perform hot work.” Below is the main part of the tolerance, where the following information is displayed in separate columns:

- the responsible employee who received the assignment;

- type of planned work;

- place where hot work is performed;

- information about specialists directly involved in the work. Not only their positions and qualifications are noted, but also information about the training received. A list of names is compiled, where each employee must sign;

- date and time of work, indicating its beginning and planned completion;

- information about what has been done during the preparatory work to ensure maximum safety;

- consent to the work of the responsible services of the facility where the work is planned;

- how the work site was prepared;

- when renewing the form, the period for which the validity of the document was extended is indicated;

- permission from those responsible to extend admission;

- information about changes in work team members;

- signature of the team leader and chief.

Responsibility for hot work without a work permit

Some employees or inexperienced managers may have the idea of carrying out dangerous hot work without the appropriate documentation. However, experienced managers will never do this. They know that work for which a permit is not issued is punishable. In most cases this is an administrative responsibility. Moreover, not only the manager personally, but also the entire organization will have to pay considerable sums. It is unlikely that after this the director will remain in his position. At best, he will be fired from his job and will be required to pay a fine.

However, there are also more serious situations. For example, managers and other responsible persons may be brought not only to administrative, but also to criminal liability. The reason for this may be emergency situations, injury or death of team members due to safety violations.

https://youtu.be/0Q_-KfJc6xk

( Video : “Safe hot work”)

That is why every experienced manager will do everything possible to not only correctly document the execution of fire-hazardous work, but also to ensure maximum safety for all workers. In addition, there are other restrictions on the performance of explosion and fire hazardous work:

- specialists must wear clean overalls that are not saturated with flammable liquids and other flammable materials;

- members of work teams can only be workers who have the necessary qualifications, which is confirmed by documents, for example, a certificate;

- if there are vapors of hazardous substances in a closed box that pose a threat of explosion, the work is postponed or completely canceled;

- welding equipment and other devices used in this case must be powered in accordance with the rules for hot work;

- It is prohibited to ignore safety rules when carrying and handling gas and other cylinders.

Work without a permit

As mentioned above, a work permit for hot work is not required if it is carried out in specially designated areas equipped in accordance with all fire safety rules. But there are situations when urgent repairs are required due to the failure of technological equipment or utility networks. That is, an emergency or extreme situation has come into force.

In such cases , emergency operations can be carried out even at night, with the caveat that the emergency area must be well lit.

But an emergency situation does not protect those responsible from violating industrial safety requirements. That is, all processes must be carried out strictly in accordance with fire safety rules. This primarily concerns the preparation of the site where OR will be carried out and equipping them with fire extinguishing equipment. If violations are discovered during events with open fire, and they lead to damage to the material and technical base or to the death of people, then you will have to answer for all of this.

Organization of permanent and temporary hot work stations, basic requirements.

Hot work locations are divided into:

- permanent: organized in workshops, workshops specially equipped for these purposes, or in open areas. It is prohibited to place permanent hot work sites in explosion and fire hazardous areas;

— temporary: most often organized during emergency repairs of equipment, cutting, heating of metal, etc.

Places for welding work outside permanent welding stations must be determined by written permission from the manager or specialist responsible for fire safety (SNiP 12-03-2001, clause 9.2.8.)

Hot work at existing explosive and fire-hazardous facilities is permitted in exceptional cases when this work cannot be carried out in permanent places specially designated for this purpose.

At each enterprise, an order must determine places for permanent hot work.

Carrying out temporary hot work is allowed only after a permit has been issued by the chief engineer of the enterprise or another responsible person from among the specialists, in agreement with a representative of the enterprise’s fire department.

To organize the preparation of the site and carry out hot work, a responsible person is appointed throughout the enterprise, including when work is performed at the site by a contractor.

Options for permit orders

The hot work permit form is a standard form. But some enterprises still use another document, which is approved by the Ministry of Economy in rules POTRO-14000-005-98. This is a shortened form of completion, which indicates only the location, the list of operations being carried out, to whom the permit was issued and the deadlines for completion.

You won't find anyone here to do the work. There is no information about the qualifications of the workers, about the training provided, about the employees who perform control, etc. The shortened version is less informative than the form from PPR-2012. And although the choice remains with the management of the enterprise, fire inspectors recommend using the work permit as a more capacious document in terms of semantic load.

How to register a logbook for work permits

Appointed work managers must register the issued work orders in a special accounting journal that corresponds to a specific type of work. The document is developed during the employment of the structural unit, and the direct clerk is responsible for monitoring the correctly entered headings in accordance with the approved nomenclature of cases.

The filling procedure is simple:

- After the company name, you must indicate the full name of the magazine.

- The start and end dates of the work must be indicated in the lower right part of the form.

- At the next stage, it is necessary to provide comprehensive information regarding: the number of the issued work order, the date of issue, a detailed description of the work according to the permit, the validity period of the document, the full initials of the person responsible for issuing the permit, the date and specific time of closing of the work order, and other notes.

The registration log must be numbered and stitched, after which the organization’s seal is affixed. To avoid declaring a document invalid, it is extremely important to avoid making all kinds of errors and typos when it is drawn up, otherwise unpleasant consequences will arise when this fact is detected by regulatory authorities.

Organization procedure

It should be noted that employees who will carry out OR must take their duties responsibly. And here it should be noted that the same welders are required to strictly follow fire safety rules, which include:

- undergoing training with an entry in a special journal and affixing signatures;

- checking the tools, equipment and devices used to ensure they are in good technical condition;

- checking the workplace for compliance with industrial safety rules;

- obtaining clean personal protective equipment.

After the end of the activities, the site, for example, must be cleaned by the same welders. And already within 2-3 hours, the person responsible for the fire safety of the facility will monitor the location of the emergency operation to ensure that there are no causes associated with the emergence of fires.

So, the permit is an important document. It is on its basis that hot work can be carried out. This is a permit confirming that the site is ready, and the work will be carried out by highly qualified workers who have access to carry out this type of event.

Video:

Recommendations for getting started

It is strongly recommended to begin fire-hazardous work exclusively during the daytime (light) hours, since during this period (the exception is force majeure and accidents) and with the direct participation of specialists with a special level of training and permits (various certificates, certificates, certificates, diplomas) ), confirming professionalism.

A work plan must be formed and approved by previously authorized specialists or heads of structural units; specialized equipment must be installed and prepared in explosive areas, thereby increasing the level of safety of the facility, turning off the power supply to devices and installations that may increase the risk of injury to humans.

Without exception, all specialists who are directly related to the work must undergo targeted training and successfully pass it, and receive individual fire protection equipment. The tools that need to be worked with are checked, and the workplace is prepared.

Important! You can begin work only after safety guarantees have been provided.

Requirements for obtaining permission

In accordance with current regulations, the work permit does not have a strictly established pattern. It can be created in free form or on a form approved by the head of the company. In this case, standard writing paper of A4 format is used and the details of the organization are indicated. The work permit is always drawn up in two copies. One remains with the manager, the second is kept by the specialist responsible for fire safety.

One permit is issued per worker . Its validity period is no more than one work shift. After which the document is handed over to the person responsible for fire safety. With prior approval, the permit to perform hot work can be extended for one more shift.

When registering, the permit must indicate a complete list of all operations performed, as well as the person responsible for fire safety. Additionally, the document indicates all fire safety measures taken and indicates the location of the work.